Starting a Proof-of-concept Test of Changing to IoT through the Use of CONTEC Products at Our Main Factory

日本

The information included in this press release is current as of the publication date. The sales conditions, price, specifications may be changed without notice.

Using the CONPROSYS™ M2M/IoT Solution to Achieve Small Lot Production of Many Products and to Further Strengthen QCD

CONTEC Co., Ltd. (listed on the Second Section of the Tokyo Stock Exchange, Securities Code: 6639) is pleased to announce that it started a proof-of-concept test at its main factory (located in Komaki city in Aichi prefecture, Japan) using “CONPROSYS™,” its IoT*2 product, in April 2016 in order to achieve small lot production of many products and to further strengthen QCD.*1

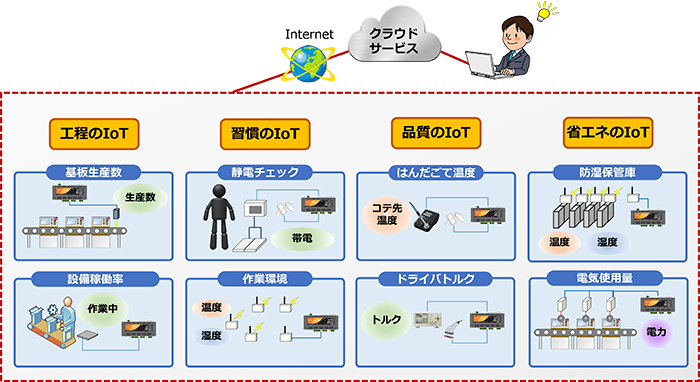

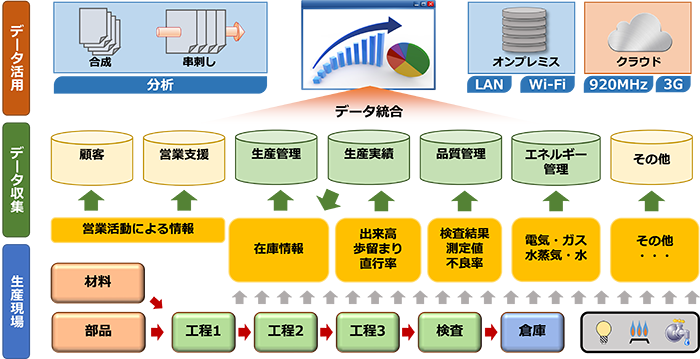

This proof-of-concept test is one part of CONTEC’s manufacturing innovation aimed at “small lot production of many products” and “enhancing QCD,” which are progressing under the name of “Conpath Project.” The following mechanisms have been introduced: “visualization of manufacturing information,” which leads to support for quick decision making in all levels of management and manufacturing and which makes efficient the use of manufacturing equipment and operator work; “monitoring of the demands for electric power from running equipment,” which is aimed at making a more economical use of energy; and “monitoring of moisture-proof storage cabinets,” which is aimed at further quality improvements. An environment has also been constructed in which manufacturing information can be accessed from anywhere in the factory by way of Wi-Fi-compatible tablet terminals. Moving forward, we will expand the visualization and analysis to the entirety of the factory, including part information and work processes. There is a plan to complete mechanisms for integrating the entirety of the supply chain, including traceability and EDI (Electronic Data Interchange, for electronic commerce), in the 2018 fiscal year.

This proof-of-concept test is also an effort to demonstrate the usefulness of CONTEC’s “CONPROSYS” product. CONTEC IoT devices (CONPROSYS M2M*3 controllers, which have obtained Azure Certified for IoT certification) have been attached to the existing equipment in the factory, and local data is being collected. The services of “Microsoft Azure IoT Suite” on Microsoft Azure, a cloud platform made by Microsoft, and the “CONPROSYS Cloud Data Services,” cloud services made by CONTEC, are being used to collect, visualize, and analyze data.

CONTEC has received the following endorsement regarding this announcement.

- Microsoft Japan Co. Ltd., Marketing & Operations Hisashi Sato, Senior Director, BG Lead, Cloud & Enterprise Business Group

- From the bottom of our hearts, we at Microsoft Japan welcome the start of this proof-of-concept test designed to change this main factory to IoT and in which Azure IoT Suite is used. The endeavor announced by CONTEC at this time provides great value as a concrete story of IoT, which solves the problems faced by the manufacturing industry amid the internationalization of business. We fully believe that the convenience, safety, and economical savings brought about by the linked system of CONPROSYS, which has obtained Azure Certified for IoT certification, and Azure IoT Suite through this endeavor will contribute to the development of the industry. Together with the IoT Business Co-creation Lab,*4 which provided assistance in the construction of this proof-of-concept test of changing to IoT, Microsoft Japan will provide support for the development of our customers’ business through our cooperative relationship with CONTEC.

*1

QCD: Quality, Cost, and Delivery

*2

IoT: Internet of Things

*3

M2M: Machine to Machine

*4

This is an IoT community established by Microsoft Japan Co. Ltd. in collaboration with TOKYO ELECTRON DEVICE LIMITED (Headquarters: Yokohama city, Kanagawa prefecture, Japan; President: Atsushi Tokushige) and that includes eight companies in the industry that promote IoT business. The goals are to spread IoT in the Japanese market and to expand business opportunities for IoT in this market.

Image of the use of CONPROSYS

Overall image of the change to IoT at a factory

- 媒体联系市场推广组

TEL

FAX

+81-3-5418-5968

联系我们

*

Company names and product names are generally trademarks or registered trademarks of each company.

*

Please use the Headquarters’ address if you wish to add an address in articles based on the content of this press release.

View all