This simulation system enables both train drivers and conductors to train simultaneously.

This simulation system enables both train drivers and conductors to train simultaneously.

With this system, training performed based on actual duties can either be done simultaneously or on an individual basis.

From Train Game Software to Realistic Train Operation Simulators

Ongakukan was originally established by Mr. Minoru Mukaiya, the former keyboardist of Japanese jazz fusion band “Casiopea,” which was quite popular in the 1980s. Although originally started as a leasing company of studio equipment taking advantage of his musical activities, a deepened knowledge of digital technology brought about through his playing of synthesizers led to the eventual development of both CD-ROM music software and the railway simulation game “Train Simulator.” Mr. Mukaiya, known himself to be a major fan of trains, put all his efforts into creation of “Train Simulator,” which turned out to be a huge hit thanks to the realistic train operating experience it provided. It was this positive response that served as the impetus for Ongakukan’s development of train simulators.

Starting with the installation of a large-scale simulator featuring HD images to a major Japanese private railway company for training use in 2006, Train Simulators have since continued to be introduced in places such as The Railway Museum, various commemorative events, as well as theme parks where visitors are able to try different work experiences. This usage of real HD video images and realistic audio in place of computer-generated graphics to create a sense of reality has proved highly popular and has gained the attention of all Japanese railway companies.

Example configuration for simulation system capable of training drivers and conductors simultaneously

Example configuration for simulation system capable of training drivers and conductors simultaneously

System Configuration

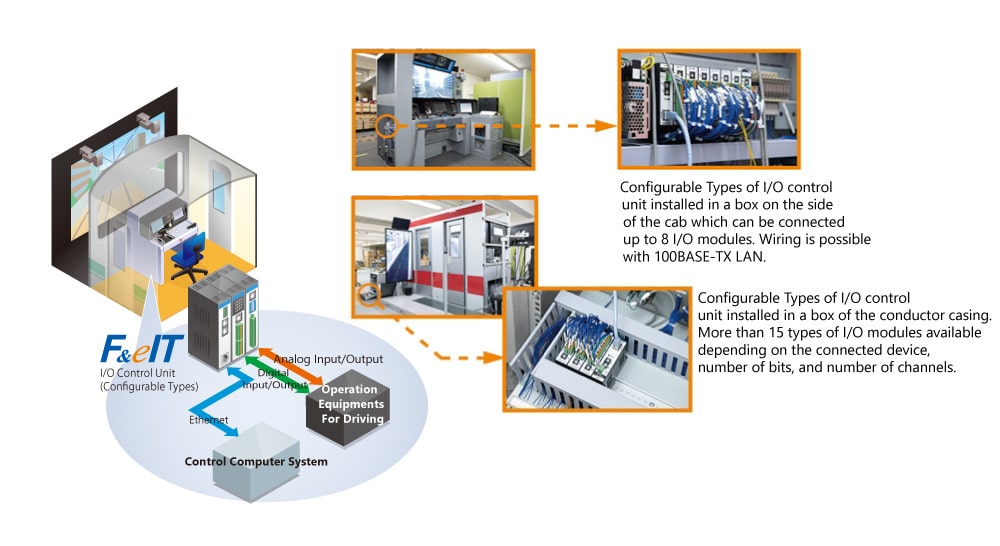

F&eIT Series for Factory Automation—Highly Reliable and Economical

In 2007, the East Japan Railway Culture Foundation opened “The Railway Museum” in Saitama City, Japan. Popular from its very opening, the four series of train operation simulators relocated from the former Transportation Museum witnessed long lines of visitors waiting to try. In 2009, Ongakukan updated simulators for the Keihin Tohoku Line 209 series and Tokaido Main Line 211 series, with E5 series Shinkansen and E233 series simulators being newly installed in 2018. In both cases, CONTEC’s F&eIT series of remote I/O systems were employed.

Train operation simulators are comprised of a system including operating equipment located at the driver’s seat, an integrated video monitor, sound speakers, and a control computer tasked with simulating the same operating environment as that of actual trains.

In recent years, the training simulators provided to railway companies mainly by Ongakukan have been designed to match actual train operations, with simulations featuring nearly the exact same behavior, response and visuals as the real thing. To achieve this requires converting large amounts of operating data into both analog and digital I/O signals.

CONTEC’s F&eIT series of minimal wiring remote I/O systems for control and monitoring processes contribute to stable operation by receiving I/O signals from the train operation side using an ultra-compact I/O device and then converting those signals into Ethernet signals using an ultra-compact CPU module. At the same time, these systems also help to minimize wiring and save space by using just one cable to establish a connection between the operation side and the computer side.

Original Railway Simulator Technology—Performing Updates for Improvements and Enhancements In-House

Ongakukan’s train simulators were designed to be as close to the real thing as possible using a unique combination of real HD video with realistic sound—something no one had attempted before. The high quality of Ongakukan’s simulator coupled with its extensive track record has garnered interest not only from Japan’s main railway companies, but also from those overseas.

In 2016, industrial-use simulators were ordered by a major railway company for use at over 80 railway worksites.

Currently, simulation systems especially developed to enable both train drivers and conductors to train simultaneously are being delivered to customers upon completion.

These simulators not only create a sense of reality using images and sound, but also seamlessly link these images and sound with operations such as train acceleration, deceleration and braking to create a real sense of train movement that is further enhanced by realistic signal displays, weather settings and even instrument needle movements. The ingenuity evident in the unique and detailed design of these simulators has garnered praise from railway professionals and is a sure sign of Ongakukan’s advanced technical prowess and dedication to creating the perfect train simulator.

In the future, Ongakukan plans to continue its efforts towards constructing a simulation system that is even more compact, labor-saving and that can be installed anywhere.

Likewise, CONTEC will continue its role as a dedicated partner in resolving problems together with customers as they continue to evolve by utilizing its IoT technical prowess.

Reasons for Choosing F&eIT

Challenges

Because the equipment and instruments used in the simulators are compliant with the same railway standards used for those on actual trains, wiring can be complex due to the large number of wires required. And, because high-speed computer processing is required to achieve a realistic feel, we were looking for ways to decrease the load placed on the I/O interfaces between equipment and instruments to the greatest extent possible.

Results

By choosing the F&eIT system, we were able to achieve the realistic response and stable operation required for our simulator, of which the same level of accuracy as actual trains is expected, while at the same time minimize wiring and save space thanks to the simplified wiring between devices and the computer. This has also enabled the simulator to evolve from being used only for display purposes to being used in actual training.

Customer Profile

- ONGAKUKAN Co., Ltd.

President Minoru Mukaiya

- In our train simulator business, consistency has been established between the planning, photography, information gathering, editing, scenario design, programming, design and installation functions and a strong desire exists to add train operation and passing sounds to real video images for an even greater sense of reality. Recently, there has been an increase in opportunities for railway workers—those most familiar with actual trains—to use our simulators for training use. It is during events such as explanatory sessions conducted following installation of a simulator for training use that we sometimes receive praise for our product, something which serves as a reward for our hard work as the creators of this system. When told that our training simulators are having a positive effect, it makes me about as happy as if I had won an award for contributing to safe train operations.

CONTEC’s F&eIT system is dedicated piece of equipment used to power our train simulators from behind-the-scenes. Both highly reliable and economical, they feature stable performance and excellent durability, resulting in us being very satisfied with them.

- ONGAKUKAN Co., Ltd.

- Ongakukan Co., Ltd. was originally established in Setagaya Ward of Tokyo and currently maintains its headquarters in the Nishi-gotanda area of Shinagawa Ward. In English, its name roughly translates to “Music Studio”. Despite its name, the company now mainly focuses on its railway business, yet much like a musician always strives to retain its artistic sense of creativity, which is why the name remains the same to this day. Furthermore, Ongakukan is involved the creation of melodies used to indicate the departure of various railway company trains and also undertakes concert-related activities.

Products used

Return to Implementation Case Studies