System Overview

This movable platform door remote monitoring system uses the CONPROSYS Series.

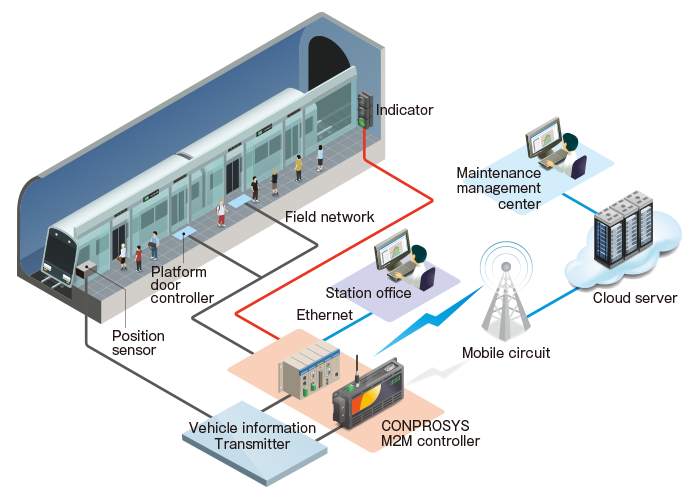

Systems Diagram

This system remotely monitors all movable platform doors for efficient maintenance service.

Not only does the system send notification of the type of detected equipment malfunction or error, it also serves as a terminal for automatically collecting information by measuring the operation count and operation time and providing preventative maintenance according to the lifetime of the parts.

In addition, the CONPROSYS Series 3G model is used for data transmission, thereby eliminating the need for wiring and simplifying installation.

Features

- Equipped with PLC communication function

CONPROSYS uses a model to communicate with the PLC and collect information. Easy settings enable collection of information from the PLC.

Contributes to improved development speed for monitoring.

- Cloud service

The cloud-based system configuration enables collective management of data from multiple locations. Since there is no need to install servers and other equipment at each station, a monitoring system can be constructed while minimizing initial costs.

- Easy control (Conprosys VTC)

The CONPROSYS Series uses the Conprosys VTC function to enable using obtained data and creation of processes including calculations and condition judgment.

Instead of having to create a program, you can create simplified control processing by lining up parts in the same way as creating a flowchart.

The obtained signals can be used to tally the operation count of the doors and calculate the operation time, and that data is then sent to the cloud server.

Related Link