System Overview

This system is for inspecting an automobile production line and prevents the release of defective products to the next process.

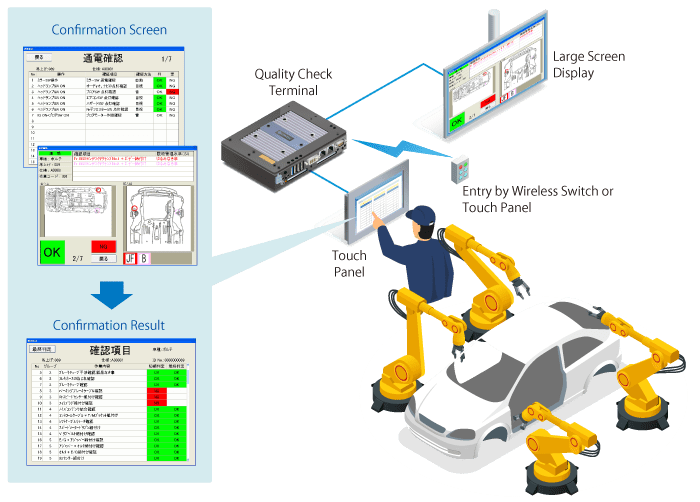

The persons in charge of inspection performs quality checks according to the check items and check positions displayed on the screen. After the quality check, they switch screens using touch panels or wireless switches to move to the next process.

Systems Diagram

The system takes in vehicle information and provides direction about the details of work and inspection according to that information.

In this system, the task is performed by referring to the work contents and acceptance criteria displayed on the screen, reducing the likelihood of the release of defective products.

Since new work instructions for new products or changed work contents are displayed and referred to, work errors and work omissions are also expected to be prevented. The use of touch panels and wireless switches enables users to build systems suited to their individual processes.

Features

- Quality check terminals adaptable to any installation environment

Compact and highly reliable box computers are used as quality check terminals.

Fanless terminals provide and maintain high durability in dusty factory environments.

- System configuration focusing on operability

We propose connection devices such as touch panels and wireless switches to achieve best operability.

It usually takes a lot of time to shut down when many terminals are involved.

We propose a system that enables users to shut down just by turning off the main power at line finishing time, thus eliminating burdensome shut down procedures.

Related Link