Touch screen technology is quickly becoming one of the primary methods of controlling and communicating with modern computing platforms. From our phones, tablets and laptops to high tech medical instruments, the touch screen interface is ever present in our lives.

Most OEMs utilize one of the 4 basic types of touch screen technology:

- Resistive Touch

- Projected Capacitive Touch

- Surface Acoustic Wave (SAW)

- Optical (Infrared and Visible Light)

Selecting the right touch screen technology for the application is key to ensuring your product functions like you want it to and that you're not over-investing is a technology that you don't need. So which touch screen technology is best for you? The following overview of the 4 basic technologies including pros, cons and common uses will help you get started.

Resistive Touch

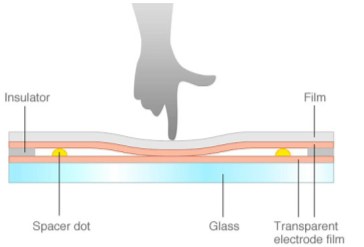

Resistive touch systems are made up of a bottom layer composed of glass and a top layer made of a flexible film. The two layers are covered with a transparent conductive material and held apart by insulating spacers. When you touch the screen, the two layers come in contact, current flows and the location of the change in voltage is noted by the touch controller. The touch controller and computer then work together to translate the touch into an "event" (such as a mouse click) located at the coordinates where your finger pressed the screen. Resistive systems while lacking in optical clarity due to the film based top layer, offer a low cost, almost foolproof touch solution. A touch can be accomplished with practically anything (finger, credit card, screwdriver, etc.), which is why you see resistive touch systems in many areas where gloves are worn or there is an excess of dirt and grime, like medical applications, industrial settings and Point of Sale (POS) systems.

Resistive Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Resistive Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Projected Capacitive

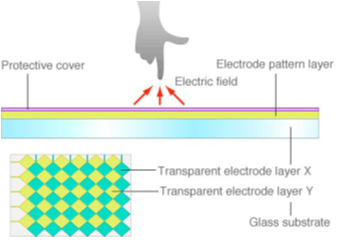

Projected Capacitive touch technology most commonly employs a two layer glass sensor structure. The capacitive layer carries a charge while the sensing layer measures the capacitive difference between points on the capacitive layer. When you touch the screen, a portion of the charge is transferred to you thus decreasing the charge on the capacitive layer. The decrease is measured and like resistive touch technology, the touch controller and computer then work together to translate the touch into an "event" at the coordinates where you pressed the screen. Capacitive touch is the predominate

technology in mobile phones, tablets and COTS touch displays. It offers very high light transmission and is extremely durable, but in order to activate a touch, you must be able to complete a circuit to transfer a charge from the screen. This can be challenging under wet conditions, when wearing thick gloves or if the screen is dirty or oily as many of you have probably experienced on your mobile phones. Prices have fallen dramatically for capacitive touch systems over the past few years, but they are still costly when compared to their resistive cousins.

Projected Capacitive Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Projected Capacitive Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Surface Acoustic Wave (SAW)

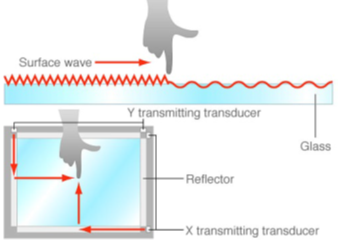

Surface Acoustic Wave (SAW) based platforms use emitting and receiving transducers along the horizontal and vertical axis of the glass sensor and reflectors along the edges of the sensor to reflect the ultrasonic signals sent from one transducer to the other. The receiving transducer is able to tell if the wave has been disturbed / absorbed when the screen is touched and calculates the location of the touch accordingly. SAW systems are very durable and have no metallic layers printed on the glass screen, which means they have very high image clarity. And, because of the way touch events are activated they can be used with almost any type of touch input provided the tip isn't too small. That said, SAW systems are more costly than resistive solutions and liquids or contaminates can sometimes trigger false touches or block out areas of the screen. As a result, SAW touch is more suitable for environments that are cleaned regularly versus those that are not (like my son's bedroom).

Surface Acoustic Wave Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Surface Acoustic Wave Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Optical

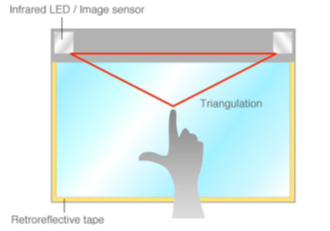

Light based systems (IR and Optical) do not employ a glass or film based top layer on the monitor. Instead, they both use frame equipped with Infrared emitters and receivers or Cameras, as well as reflectors to create an invisible grid across the surface of the screen. When an object interrupts the grid, the sensors or cameras are able to locate the touch point via triangulation and communicate the event to the computer. Optical based systems have the highest image clarity of all touch technologies, but the high cost and addition of a frame around the display makes them somewhat impractical for smaller sized displays and industrial environments. Both solutions are prone to false touches as they are also sensitive to liquids, dirt and other types of buildup, but for large screen applications in excess of 40", light based solutions dominate.

Opatical Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

Opatical Touch Screen Technology Diagram (Image Courtesy of Dive Displays)

So there you have it, an overview of the fundamentals of today's touch technologies. As you can see, there are important differences between them in terms of image quality, cost, durability and their ability to handle different environmental conditions. If you're sourcing a touch display for your organization, it's important to fully understand your requirement before you decide on a technology. I encourage you to DOWNLOAD your free copy of the Contec Display / Touch Screen Requirements Specification Form in my previous blog: 2 essential steps for OEMs sourcing a display or touch screen. If you're not sure if you need a custom or a commercial-off-the-shelf display you can learn more here.