A New Series Specializing in Remote Monitoring and Data Logging.

Contec Releases Its New Product: CONPROSYS™ Telemeter Series

Africa、Asia、Europe、Japan、Middle East、North America、Oceania、Latin America

The information included in this press release is current as of the publication date. The sales conditions, price, and specifications may be changed without notice.

Contec Co., Ltd. (listed on the Second Section of the Tokyo Stock Exchange, Securities Code: 6639—hereinafter "Contec") is pleased to present the CONPROSYS™ Telemeter Series under the CONPROSYS™brand, Contec’s comprehensive industrial IoT product brand for remote monitoring and data logging. Sales for the new series began July 17, 2018.

CONPROSYS™ Telemeter Series

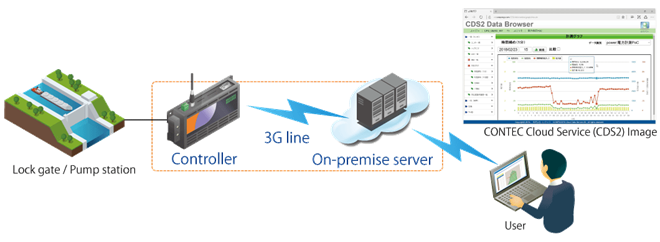

The CONPROSYS Telemeter Series is a controller with the functions necessary for remote monitoring systems, including web-based monitoring, file saving, and event monitoring (e-mail notifications, etc.). In addition to the ability to collect data directly from sensors and actuators through included digital input/output, analog input, and counter signal input terminals, devices also offer a Modbus Master function that enables communication with Modbus slave devices including PLCs from various manufacturers as well as the CONPROSYS nano Series. Collected data can be displayed graphically using CONPROSYS HMI—the included screen creation software—and monitored remotely from a variety of web browsers. The Telemeter Series also supports CONPROSYS Cloud Data Service 2 (CDS2)*1, Contec’s own cloud data service, allowing for the development of a comprehensive monitoring system with multiple bases.

The CONPROSYS Telemeter Series allows for completely programming-free configuration of settings and its operation for web-based monitoring, file saving, and event monitoring, all from a web browser. This allows users to drastically reduce the time and costs that come with developing a remote monitoring system.

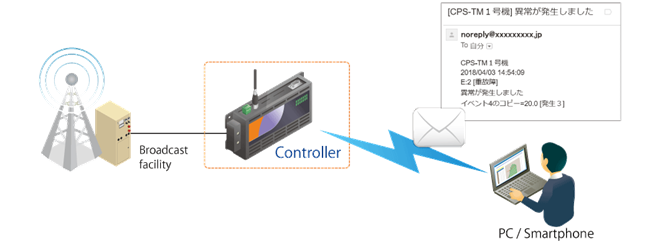

Through this new series, Contec is dedicated to meeting the ever-increasing needs of remote monitoring systems in the fields of energy generation, water treatment, and building automation. In addition to significant reductions in regular system management efforts, the CONPROSYS Telemeter Series is also capable of sending e-mail notifications to smartphones or PCs in the event of an abnormality, ensuring faster maintenance support and contributing to a reduction in the Total Cost of Ownership (TOC).

Case study 1 — Broadcast Facility Monitoring System in Remote Locations

- Reduced costs of network construction compared with proprietary lines by using 3G network

- Fewer periodic inspections thanks to e-mail notifications in the event of an abnormality

Case study 2 — River Water Level Monitoring System

- Drastic reduction in regular management rounds thanks to comprehensive water level monitoring

- Remote monitoring for inaccessible locations using 3G networks and an on-premises server (separate consultation required) and cloud services

Software Features

-

Operation is possible by configuring only the settings required for remote monitoring.Completely programming-free setup for immediate remote monitoring.

Data collection, monitoring, file saving, event monitoring, and external device communication functions are included as standard. The ability to use these functions with only simple setting configuration makes it possible to build a remote monitoring system quickly and at a low cost

-

CONPROSYS HMI screen creation software

Telemeter Series products come with CONPROSYS HMI, which allows for monitoring input signal statuses by arranging the prepared items side by side. The ability to intuitively create screens using only a web browser means there is no need for knowledge of programming languages or for a special development environment. Creating a screen is as simple as dragging and dropping the desired items from a wide variety of prepared display components.

Hardware Features

-

Various available interfaces

The CONPROSYS Telemeter Series offers 4 isolated digital inputs (with 2 assignable to 2-point insulation counter inputs), 2 semiconductor relay outputs, 2 channels of isolated channel-to-channel analog current input, 1 channel of isolated RS-422A/485, 1 channel of RS-232C, a LAN port, a USB port, and a 3G communication module (CPS-TM341GMB-ADSC1-931 only).

Related Link

- Sales Promotion Group, Sales Division

TEL

FAX

+81-3-5418-5968

Contact Us

-

※

Company names and product names are generally trademarks or registered trademarks of each company.

-

※

Please use the Headquarters’ address if you wish to add an address in articles based on the content of this press release.

View All News Releases