System Overview

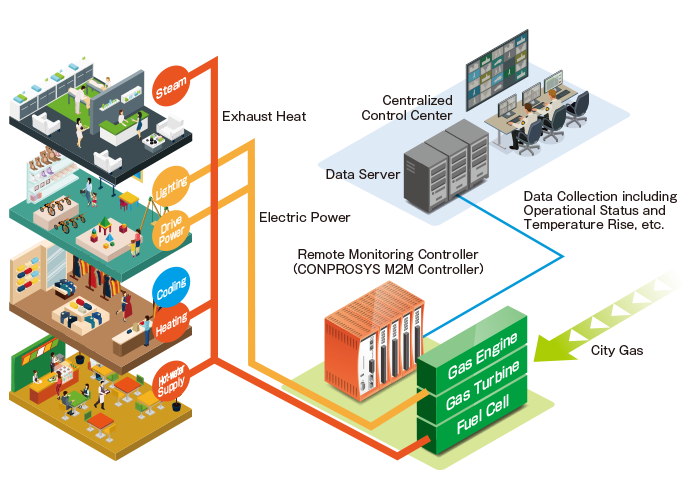

This system performs unified management of the operational status of a gas cogeneration system from the centralized control center.

Systems Diagram

The system enables quick and accurate repair in the event of breakdown and provides preventive measures by collecting data from gas engines and gas turbines.

Cooperation with the data server allows the centralized control center to monitor whole information collected from other facilities.

Collected data on operational status and operating rates is used as a measure for planning a maintenance program.

Features

- Flexible interface

The remote monitoring controller of this system uses the stack type CONPROSYS, allowing flexible configuration in accordance with the different scales of monitoring systems.

- Task control (CONPROSYS VTC)

Using the collected measurement data, the CONPROSYS VTC function performs filtering of unnecessary data, calculation, and conditional judgment without the need for programming.

The system may also be used to determine abnormalities and send a notification.

- Web monitoring (CONPROSYS HMI)

The system is equipped with the CONPROSYS HMI function that provides a graphical presentation of collected signals.

Using CONPROSYS HMI, customers can easily set up a monitoring screen with a Web browser to create a local monitoring system.

Related Link