Modernize Your Factory With Our Line of M2M/IoT Controllers (Video)

Africa、Asia、Europe、Japan、Middle East、North America、Oceania、Latin America

Offering Industries M2M/IoT Capabilities with a Reduction in Operational Costs

Our world is ever changing and technology is one advancement that happens at a rapid pace. Machine-to-Machine (M2M) communication has become increasingly important. Data collected from various devices is being shared over the Internet of Things (IoT) to create a wide range of benefits that enable remote monitoring and visualization in multiple industries.

CONPROSYS is the Contec solution – providing a simple and affordable way to implement IoT/M2M communication. CONPROSYS saves money through increased efficiencies, reduced down time of machinery, predicative and preventative maintenance and improved data analytics. It supports a variety of equipment interfaces for analog and digital I/O.

What’s unique about CONPROSYS is the variety of modules available. CONPROSYS is offered as an integrated type or a configurable type which maximize the ability to be integrated into many applications. The Integrated Type is an all-in-one device. The Configurable Type offers a high level of expandability. Both of the models support a range of ambient temperatures and can be mounted to industry standard DIN rails.

This programmable logic controller is a web browser application that is easy to integrate into custom monitoring screens, virtually no experience is necessary. It supports task programming like setting alarms, conditions and external communication. Once the data is collected, it is sent to the cloud server or a wired network. Up to 30 devices, using different interfaces, can be supported at the same time. SCADA and HMI systems are used to collect data analytics about equipment performance. CONPROSYS facilitates a flexible and scalable IoT network where security is achieved through the SaaS model.

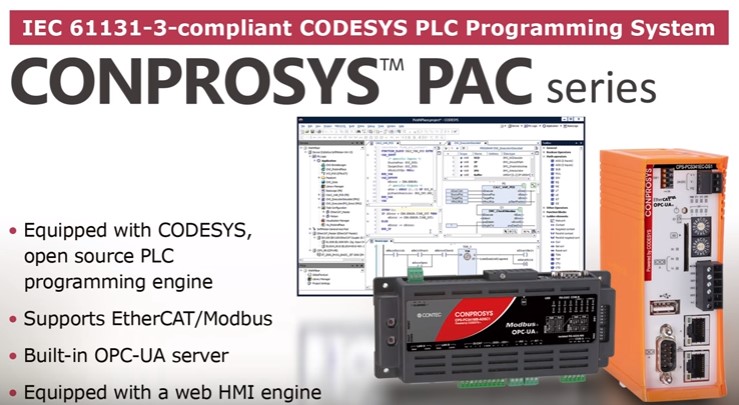

The CONPROSYS PAC Series comes with CODESYS and supports EtherCAT open networks. This programming language is quite popular in the global technology market.

It’s no wonder why our parent company in Japan, Contec Co,Ltd. has incorporated our product in their Komaki Factory. CONPROSYS has resulted in reduced operational costs through an increase in productivity and efficiency.

- Benefits of CONPROSYS proven at the Komaki Factory include:

- Monitoring production volume

- Monitor efficiency and status of each production cell

- Production assembly and test monitoring for efficiency, cycle time and quality

- Automated environmental monitoring and process control

- Automated production quality monitoring and controls

- Monitor and verify production tooling parameters and calibration

- Collected data can be monitored via the cloud in real time

- Monitoring accuracy and calibration of soldering station equipment

- IoT capabilities allow remote monitoring of all factory machines from a single or multiple stations

- Data collected enables the user to increase productivity and decrease operational costs

The benefits of CONPORSYS extend far beyond the factory floor. CONPROSYS can be used in a variety of industries. We invite you to experience CONPROSYS through a live virtual tour or make plans to schedule a tour at the Komaki Factory in Japan.

Request a Demo today and see how CONPROSYS will benefit your organization.