This technical column introduces the key points of the seminar

"Factory Automation: How to use the familiar Raspberry Pi with industrial PLC? - All-in-one industrial Raspberry Pi based PLC with CODESYS for flexibility and cost savings -"

held on September 27, 2024.

Contents

Potential industrial applications combining Raspberry Pi and software PLC

First, we will discuss the use of Raspberry Pi and software PLC in industrial applications.

This solution introduced by our company aims to automate factories using the familiar Raspberry Pi.

The Raspberry Pi was originally developed for educational purposes, but due to its low cost and flexibility, it is now used in industrial applications.

Therefore, our company has developed a new all-in-one PLC based on the Raspberry Pi, achieving high reliability and stable long-term supply suitable for industrial applications.

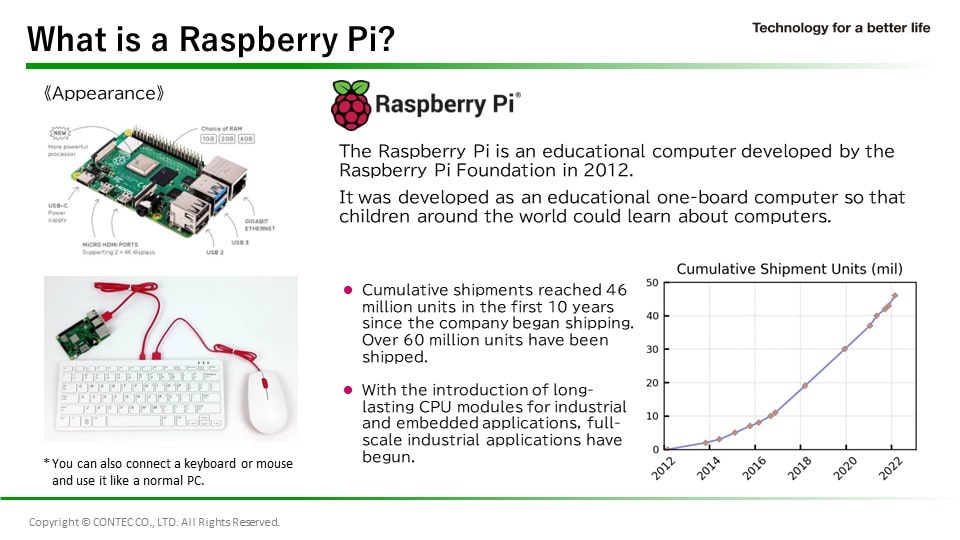

What is a Raspberry Pi?

Let's take a look at the basic features of the Raspberry Pi and how you can use it.

The Raspberry Pi is characterized by its simple configuration and ease of use, and has been praised for its ability to utilize a standard operating system (Raspberry Pi OS) while keeping operating costs low.

The Raspberry Pi also has a rich programming environment, such as Python and Node-RED, and is open source, making it easy to learn and provide a wealth of information.

Furthermore, the Raspberry Pi is easy to extend for industrial applications. Specifically, various functions can be added by using an extension board called "HAT."

Our company also offers an extension board that supports HAT, allowing for more flexibility in building automation systems.

The Compute Module series of the Raspberry Pi for embedded applications consists of the CPU, memory, and storage parts of the Pi mounted on a board.

The necessary interfaces are then added to make it possible for industrial applications.

Thus, a variety of Raspberry Pi models have evolved to meet the needs of industry.

In addition, combining a software PLC with a Raspberry Pi enables cost-effective and flexible factory automation.

Evolution of CODESYS supported software PLC and IoT

CODESYS is a software PLC developed by German company CODESYS, which has greatly contributed to the advancement of Industry 4.0 and IoT.

First of all, a PLC (programmable logic controller) is a control device widely used in factory automation and robot control.

However, conventional PLC has been difficult to transfer between different manufacturers because a specific manufacturer provides the hardware and software together.

CODESYS is provided as a separate software that can be installed on industrial computers running Windows, Linux, etc., and can be used on a variety of hardware.

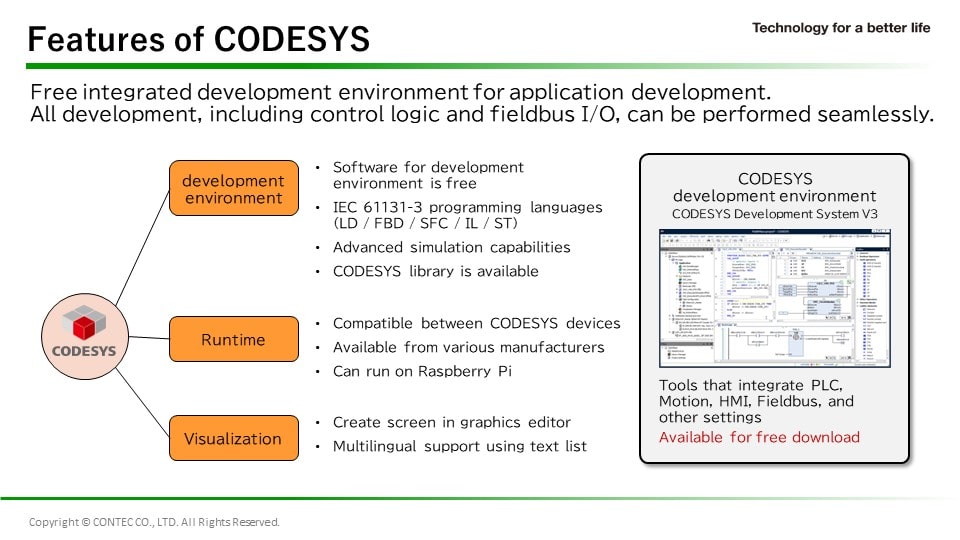

Features of CODESYS

One of the key features of CODESYS is its free integrated development environment.

This development environment enables seamless development of control logic and fieldbus I/O, ensuring compatibility between devices.

This allows programs that run on Windows to run on Linux without any problems.

CODESYS is used by more than 400 companies worldwide, and is included in many products, providing an environment where you can take advantage of know-how and programs.

Recently, hands-on applications running on the Raspberry Pi are available for easy testing.

CODESYS also has a web server function that displays a monitoring screen in a web browser for easy visualization.

This allows users to remotely monitor and manage the status of devices on the web, meeting the needs of IoT.

The CODESYS development environment supports 6 programming languages (LD, SFC, FBD, ST, IL, CFC): 5 programming languages conforming to the international standard IEC 61131-3 plus original languages.

This makes it easy to transfer programs between different manufacturers, and by combining multiple languages, you can develop programs that take advantage of each language's strengths.

In addition, CODESYS has a built-in simulation function, so you can check program operation even when no device is connected, and efficiently debug programs.

This integrated development environment has a similar interface to Microsoft's Visual Studio and is easy to use, allowing you to create a new project, configure I/O, program, debug, create visualizations, and deploy.

In particular, the visualization function makes it easy to build HMI screens and create GUIs for monitoring various data.

Programming and Application Proposal for Raspberry Pi Compatible Controller by CODESYS

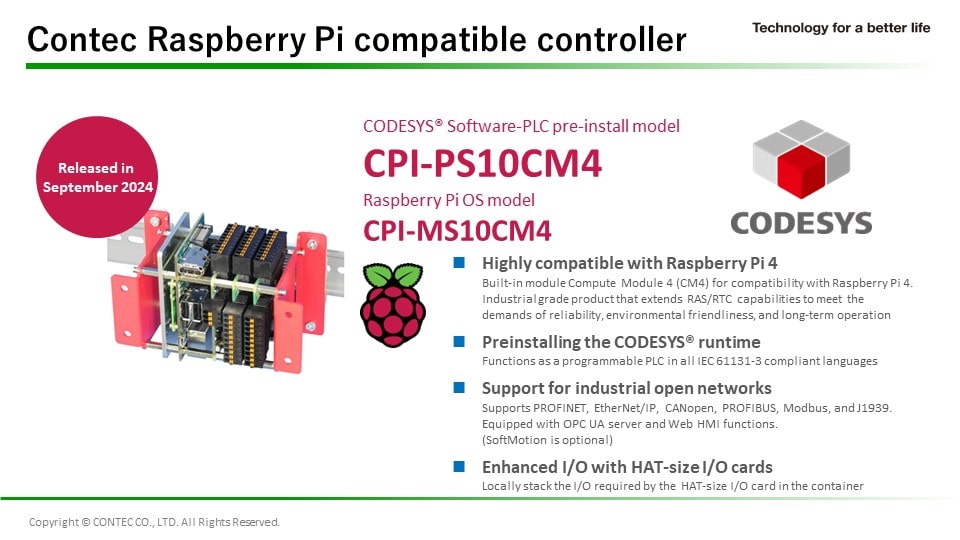

Contec Raspberry Pi compatible controller

Our company has announced the CPI-PS10CM4 and CPI-MS10CM4 Raspberry Pi-compatible controllers.

The CPI-PS10CM4 comes pre-installed with CODESYS and is designed for immediate industrial use. By contrast, the CPI-MS10CM4 comes pre-installed with only the Raspberry Pi OS, providing a flexible choice for existing Raspberry Pi users.

The product can stack multiple HAT-sized boards and provide digital and analog input/output capabilities.

This gives users the flexibility to change configurations based on their needs.

CODESYS comes pre-installed with a Standard S license, which provides up to 512 I/O channels. Additionally, motion control functions can be added from the CODESYS store as needed.

Our company offers a range of HAT expansion boards with digital I/O, analog I/O, and counter functions that can be connected directly to the Raspberry Pi.

Up to eight HAT expansion boards can be stacked for flexible expansion.

CODESYS also supports Modbus-TCP for remote I/O input and output.

It works easily with Modbus-enabled devices such as temperature and power meters to streamline data collection and management in industrial environments.

It is also compatible with EtherNet/IP, and can link data with PLC made by other companies, improving the convenience of system integration.

This makes it easy to integrate into existing facility environments, and enables flexible operation for various applications.

In terms of system execution speed, according to our company's tests, it has been confirmed that the system has the same processing performance as MHI's MELSEC-Q and high real-time performance.

We believe that this performance can be used in industrial applications where stable operation is required.

The Raspberry Pi compatible controller is intended for use in situations where the same performance as Omron's or Mitsubishi's PLC is required, but it is difficult in terms of cost, or where it is impractical to develop an independent controller.

The seminar also covered security measures in detail.

Specifically, for our company's Raspberry Pi compatible controller, firewall and endpoint measures are recommended to prevent unauthorized access within the network.

It is also important to use communication monitoring devices on the network to detect abnormal data flows, close unused ports, update the OS, and other basic measures.

These measures can reduce security risks.

As described above, our company's Raspberry Pi compatible controllers with CODESYS are easy to use and highly scalable.

As a result, we expect them to be of great use as an easy option for companies looking to improve efficiency and reduce costs in industrial settings.

Our company Remote I/O Products - CONPROSYS nano and IO-Link Master -

Finally, we introduce our company's remote I/O products, CONPROSYS nano and IO-Link master.

Remote I/O Products

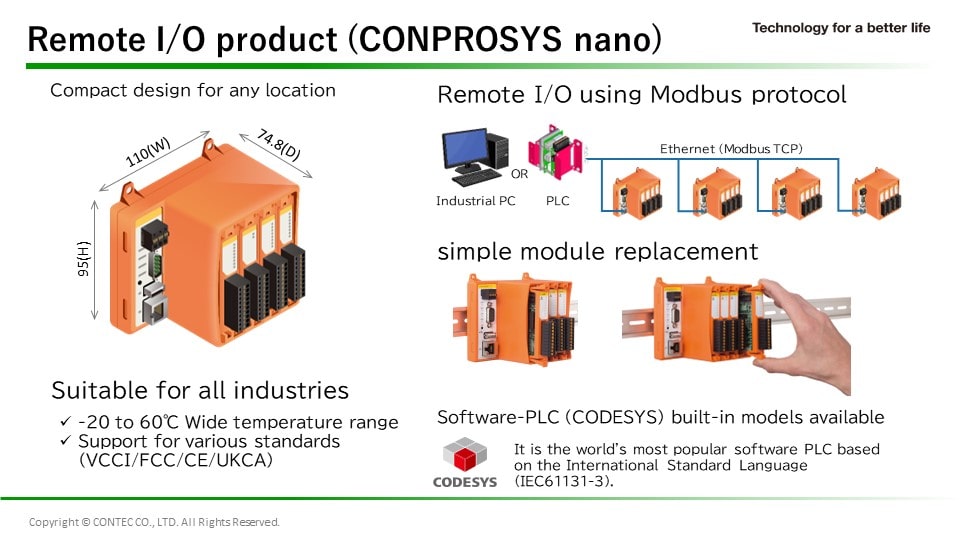

CONPROSYS nano is attracting attention as a flexible remote I/O product.

This product has a 4-slot coupler shape, allowing you to freely combine modules such as digital input/output and analog input/output as needed.

This makes it easy to build a remote I/O system using Modbus-TCP remote access.

This product is also available with CODESYS software PLC, and although it has a certain amount of CPU power, it is limited in processing heavy loads.

However, this product has sufficient performance for applications that require a fast response remotely, and it can run CODESYS programs locally.

Next, we introduce the IO-Link Master remote I/O product.

This product supports multiple protocols and supports different communication protocols such as EtherNet/IP and PROFINET by switching switches.

It is also dust-resistant and waterproof according to IP67, and has 8 channels of IO-Link ports.

This makes it easy to connect IO-Link compatible sensors, motors, etc., and provides scalability.

In this way, various equipment and sensors can be efficiently integrated into the network, enabling flexible on-site response.

The CONPROSYS nano and IO-Link master are designed for efficient remote management in industrial settings.

Remote I/O is becoming increasingly important with the digitization of modern manufacturing and infrastructure, and our company offers the best solution for this trend.

We hope you will take this opportunity to improve your business efficiency and productivity by using our company's Raspberry Pi compatible controllers and remote I/O products.

Product Information Pages

Related Content

Back to Blog Top