This technical column is a re-edited version of an indexPro iP-special, published in April 2025 by our company.

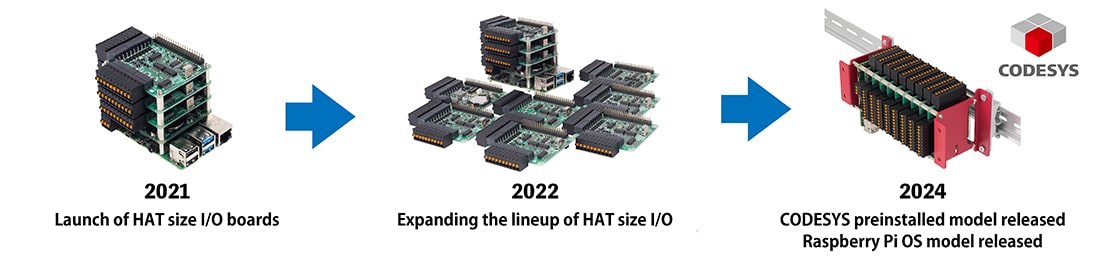

History of Raspberry Pi Product Development

Focusing on the accelerating use of Raspberry Pi in industrial applications, we entered the Raspberry Pi market in 2021 and began selling HAT (Hardware Attached on Top) size I/O boards.

In 2022, we expanded our lineup with the aim of improving general-purpose open technology. In 2024, we released CODESYS pre-installed models and Raspberry Pi OS models.

In 2025, we plan to introduce more new products to increase user choice.

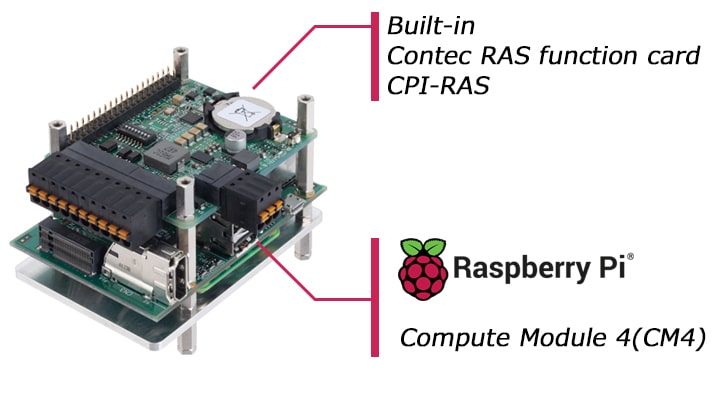

Compact All-in-One PLC for Integration

Contec’s compact embedded PLCs are original card PLCs built around the latest embedded Raspberry Pi module, Compute Module 4 (CM4). Designed for industrial automation and IoT devices, Contec’s two newest models include a PLC pre-installed with CODESYS, and a Raspberry Pi OS-based model for users developing software in-house.

Features

- Highly compatible with Raspberry Pi 4 : Industrial grade products with enhanced reliability and environmental resistance

- Pre-installed with CODESYS : High-speed, high-capacity PC technology for advanced PLC functionality

- I/O expansion with HAT-sized cards : Comprehensive application of Raspberry Pi periphery devices

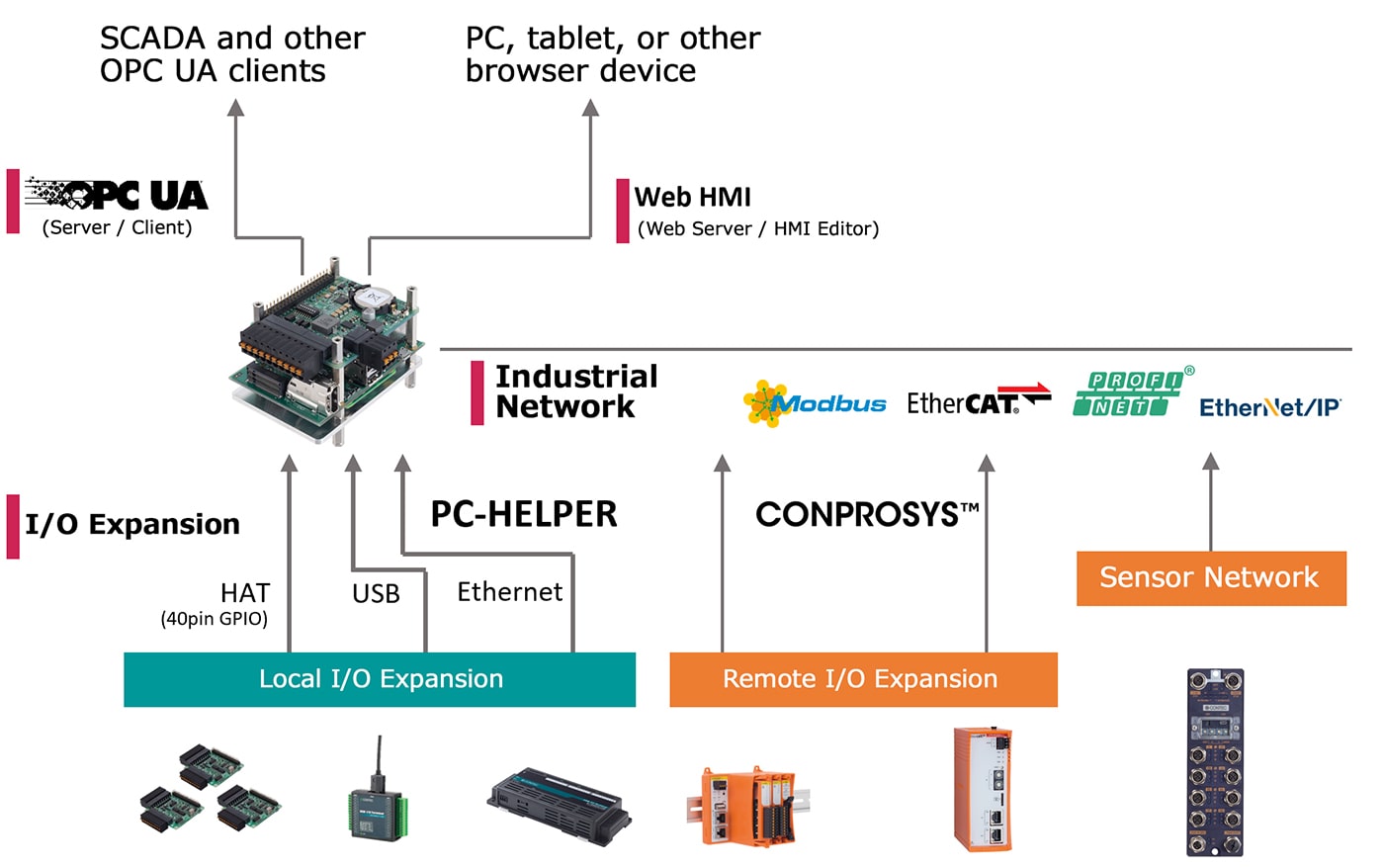

- IoT and industrial open network support : Equipped with Web HMI and OPC UA server/client functionality

Highly compatible with Raspberry Pi 4

Originally developed as an instructional card in 2012, the Raspberry Pi—now in its fifth generation—has continued to evolve while staying true to its original concept. To date, more than 60 million units have been shipped, including industrial-grade Compute Modules. The Raspberry Pi Foundation reports that more than 60% of its sales in 2023 were for industrial and embedded applications. To ensure high compatibility with Raspberry Pi 4, Contec has adopted Compute Module 4 (CM4) for its products. Contec has also developed RAS function expansion cards equipped with essential features for industrial controllers—including RAS/RTC functionality, a watchdog timer, and hardware monitoring—to deliver the reliability and environmental resistance required for industrial applications.

Specifications [CPI-PS10CM4]

- Quad-core Cortex-A72 (ARMv8) 64-bit SoC @ 1.5 GHz

- 2 GB high-speed DDR4 memory

- 16 GB eMMC storage

- Basic processing speed (LD instruction): 1.86 ns (*Measured by Contec)

- Applied processing speed (ST instruction): 2.06 ns (*Measured by Contec)

- Program capacity: 3 MB

- Number of I/O tags: 512 (*16-bit data counted as one tag)

- Interfaces: 1× 1000 Mbps LAN, 1× 100Mbps LAN, 1× HDMI, 2× USB

- M.2 Key M NVMe socket

RAS function expansion card

The RAS function expansion card adds RAS functionality, RTC functionality, and 8–28 VDC power supply input functionality to the Raspberry Pi. This HAT-sized expansion card connects via a 40-pin header for stackable connection and provides the Raspberry Pi with the enhanced scalability and maintainability required for industrial computer applications.

Specifications

Specifications

- RAS (Reliability, Availability, Serviceability) function

- Built-in RTC (real-time clock)

- Built-in WDT (watchdog timer)

- Power switch functionality

- 8 to 28 VDC power supply input

- 5 VDC 500 mA high-output, high-efficiency power supply with noise filter

HAT-sized design for stacked connections of up to 8 cards

FA control and measurement control systems require large numbers of signal inputs and outputs. Due to HAT specifications, conventional Raspberry Pi could only support a single I/O card. With Contec’s proprietary multi-stage connection technology, however, stackable connections of up to eight I/O cards are possible.

HAT-sized cards and optional products

Contec offers a wide variety of expansion cards and various options for adding periphery devices for FA control systems utilizing Raspberry Pi. The HAT-sized expansion cards connect via a 40-pin header, allowing easy addition of various I/O required for measurement and control. Installation is also incredibly simple with Contec’s DIN rail mounting kit. Compact embedded PLCs are often installed inside control panels as card-type PLCs and housed within metal enclosures. This provides excellent resistance to static electricity, spurious signals, noise, and shock, ensuring reliable operation in industrial environments.

Specifications

- Push-type terminal block for easy wiring

- Stacked connections of up to 8 boards

- API compatible with PC expansion cards(With development asset reusability across multiple platforms)

- Python and GCC sample programs included

- Wide variety of input/output types

- Photocoupler-isolated bus

- Usable over a wide range of operating environment temperatures (-20 to 60°C / -4 to 140°F)

Going forward, Contec plans to actively expand the use of Raspberry Pi in industrial applications by developing specialized cards, including analog input/output cards, serial communication cards such as RS-232C and RS-422A, and custom-designed cards tailored to specific needs.

Pre-installed with CODESYS Runtime

CODESYS is used by over 400 OEM manufacturers worldwide, with more than one million licenses shipped annually. The CODESYS Store offers a variety of licenses to suit different applications, and Contec’s compact embedded PLCs come pre-installed with the CODESYS Control Standard S license. This enables users to leverage the wide range of Raspberry Pi periphery devices to build diverse control applications.

CODESYS supports six IEC 61131-3 standardized programming languages, including LD (Ladder Diagram) and FBD (Function Block Diagram), allowing for smooth migration from traditional PLCs. As globally recognized software that is independent of specific hardware, CODESYS is easy for software engineers to work with and offers excellent maintainability.

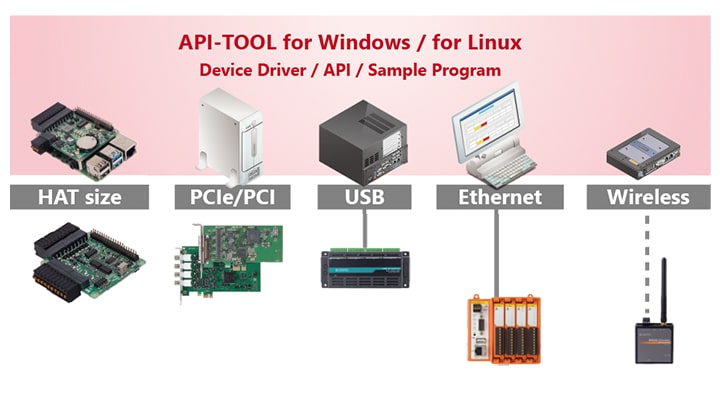

Multi-platform support

For those looking to partially transition from a PC-based system to a Raspberry Pi-based system—or scale up a Raspberry Pi-based system to a PC-based one—Contec makes migration easy with minimal program modifications.

For example, when using PC expansion cards that connect via PCI bus, USB, Ethernet, or wireless, Contec’s integrated driver software absorbs hardware differences, allowing for simple API-level program migration. Sample API programs are also provided free of charge to help streamline development.

Enhanced network and IoT linking

Contec’s compact embedded PLCs are equipped with a wide range of industrial network communication functions enabling support for Modbus, EtherCAT, PROFINET, and EtherNet/IP. This enables communication control with Contec’s CONPROSYS nano series remote I/O products and M2M communication with other FA controllers.

Meanwhile, OPC UA server/client and Web HMI capabilities also allow use as an all-in-one controller with integrated IoT capabilities to implement DX. This eliminates the need for additional devices, helping to reduce overall system costs.

New business solutions from Contec

Challenges with conventional PLCs and in-house development

Traditionally, general-purpose hardware PLCs have been widely used for small-lot systems. For high-mix, low-volume production, however, this approach often proves costly and leads to heavy dependence on specific manufacturers. In addition, the hardware and programming languages often differ between manufacturers, creating further challenges. Although in-house development can offer cost advantages for large-lot production, as development complexity increases and user requirements become more advanced, the increased workload for programming and software development becomes a significant challenge.

To address these challenges, Contec offers a compact all-in-one embedded PLC designed to strike the optimal balance between development costs and network functionality. Positioned between general-purpose hardware PLCs and full in-house development, it is ideal for small- to medium-lot production with high-performance requirements.

Advantages to a compact all-in-one embedded PLC

- Hardware, OS, CODESYS—all in one place

Powered by Raspberry Pi, Contec’s PLC comes fully equipped with an industrial-tuned Linux OS and CODESYS, eliminating the need for setup during installation. Contec also addresses key early-stage development challenges such as hardware selection, OS implementation, and system setup, allowing users to initiate system development easily and quickly.

- Reduced engineering costs

For equipment manufacturers, rising engineering costs often pose a greater challenge than manufacturing costs. With support for IEC 61131-3-compliant programming languages widely used by developers, this PLC makes it easier to secure skilled engineers. Moreover, because it is not hardware-dependent, existing engineering resources can be fully leveraged, helping to reduce additional training costs.

- Long-term reliability and stable supply

As an industrial-grade Raspberry Pi module, the PLC is backed by a stable supply framework and features RAS/RTC function extensions, a reliable and environmentally resistant design, a watchdog timer, and hardware monitoring, ensuring the reliability and quality required for continuous operation in demanding FA environments.

- Easy maintenance and repair

The combination of globally trusted Raspberry Pi hardware and Contec’s proprietary I/O expansion technology minimizes implementation risks. In addition, because the product is delivered with development steps already completed, the PLC offers flexibility for easy replacement and expansion if needed.

Targeted applications and markets

- FA / industrial automation

- Control equipment and sensor management for machine tools, conveyor lines, etc.

- IoT/smart factories

- Equipment manufacturers / OEM companies

Summary

The Raspberry Pi, built on ARM architecture, can be considered a type of PC with the added advantage of easy access to a wide range of periphery devices and abundant resources for practical use. As interest in industrial applications continues to grow, information on integrating specific sensors, communicating with periphery devices, and connecting to the cloud will become increasingly accessible to meet a diverse range of needs. Leveraging its technical expertise cultivated through developing user-friendly FA products, Contec is dedicated to further strengthening its Raspberry Pi business by advancing the development and sales of expansion cards and software with the goal of positioning software PLCs as a new solution option.

Contec will continue to support the evolving needs of the measurement control industry by developing hardware and device drivers to ensure smooth adaptation to technological advancements.

Product Information Pages

Related Links

Back to Blog Top