A switching hub is an essential device for connecting industrial PCs, PLCs, and other controllers to a network.

Switching hubs vary widely, and the required performance depends heavily on the intended application and operating environment. In large-scale facilities such as factories or public transit systems—where downtime cannot be tolerated—devices must deliver both high performance and proven reliability.

This tech blog explains the fundamentals of industrial switching hubs and introduces the main points to consider when selecting the right model.

Contents

What Is a Switching Hub?

Before diving into industrial models, let’s first review the basic functions and roles of a switching hub.

A Device That Connects Controllers to a Network

A switching hub connects industrial PCs, PLCs, and other controllers to a network via LAN cables. Equipped with multiple ports, it manages data transmission and reception between connected devices.

Switching hubs are found everywhere—from homes and small offices to large-scale office buildings and factories.

Differences from Routers

Switching hubs and routers are both network devices, but they serve very different purposes.

A switching hub simply expands LAN ports; it cannot connect directly to the Internet. For internet connectivity, it must be paired with another device, typically a router.

A router, on the other hand, assigns IP addresses and manages communication with external networks—acting as the bridge between the Internet and the internal network.

Differences from Repeater Hubs

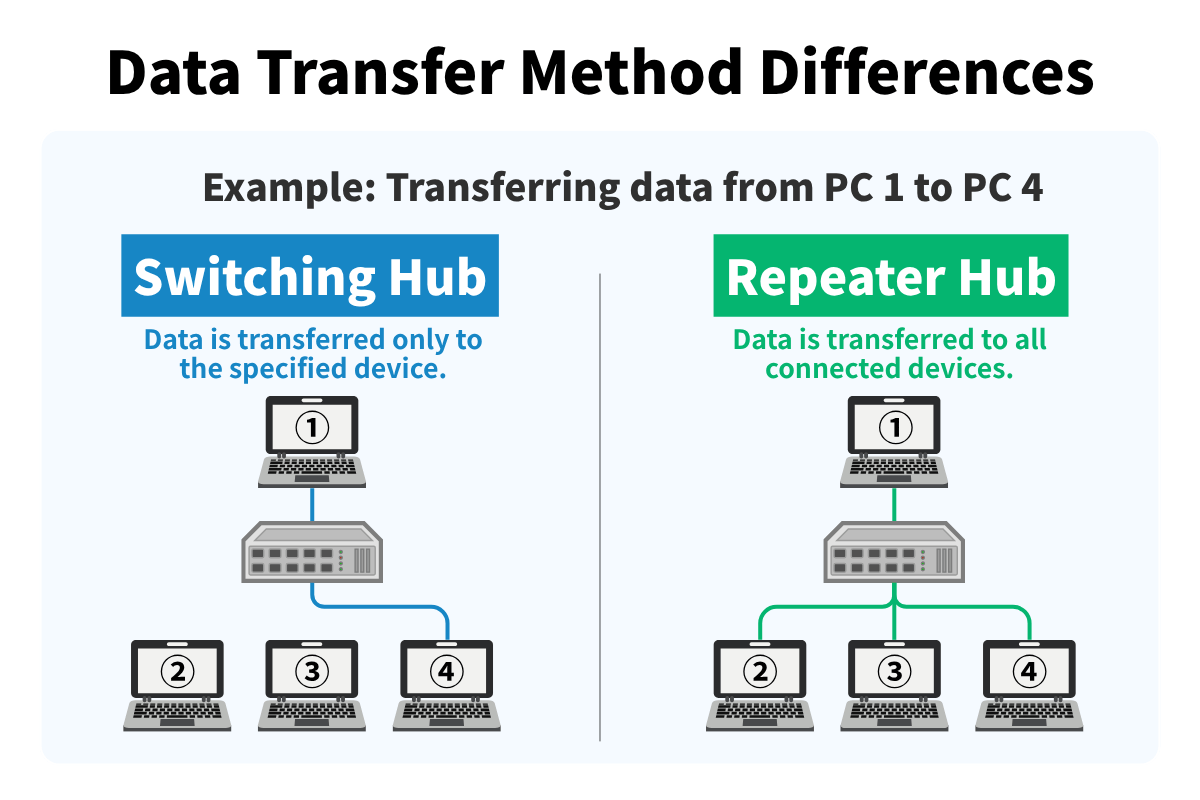

Data Transfer Method Differences

Example: Transferring data from PC 1 to PC 4

Switching hub // Data is transferred only to the intended device.

Repeater hub // Data is transferred to all connected devices.

A switching hub transmits data only to the intended device.

By storing the MAC addresses of connected devices and transmitting data only where it is needed, a switching hub ensures efficient use of network resources.

A repeater hub, on the other hand, performs only basic physical functions like amplifying signals or reshaping waveforms, making its operation and structure simple. While repeater hubs were once common, they have largely been replaced by switching hubs and are seldom used today.

However, because repeater hubs transfer the same signal to all ports, they can still be useful for tasks like packet capture in debugging or troubleshooting.

The key difference between switching hubs and repeater hubs lies in how data is transferred.

Repeater hubs transmit data to all connected devices, creating unnecessary traffic and reducing network efficiency.

Switching hubs transmit data only to the intended device, making them more efficient and less error-prone than repeater hubs.

What Is an Industrial Switching Hub?

Switching hubs designed for large-scale facilities—such as factories or transportation infrastructure—are commonly called industrial switching hubs. In contrast, those used in homes or small offices are often referred to as consumer switching hubs.

Both types fulfill the same basic role: connecting PCs, PLCs, and other controllers to a network via LAN cables.

However, industrial switching hubs are designed to ensure stable operation under conditions far harsher than those in a typical office, where high temperatures, vibration, or absolutely no tolerance for downtime are the norm.

To achieve this, they must satisfy specific requirements such as the following.

- Environmental resistance: Capable of enduring harsh conditions such as temperature variations, vibration, dust, and water.

- Reliability: Capable of delivering continuous, stable operation with no unplanned stoppages.

- Redundancy: Supports dual power supplies and network redundancy so that operations can continue even in the event of a failure.

- Manageability: Supports managed switches (with monitoring and control functions) for efficient monitoring and quicker fault response.

The table below highlights the main differences between consumer and industrial switching hubs.

How to Select an Industrial Switching Hub

Industrial switching hubs are engineered with specifications that anticipate much harsher operating conditions than consumer models.

When selecting an industrial switching hub for real-world applications, pay close attention to the following six factors.

Number of ports

Mounting method

Environmental resistance

Dual power supplies

Wide-range power input

Auto MDI/MDI-X

Number of Ports

The number of ports on an industrial switching hub varies by model, so select a hub that provides the necessary capacity.

Factor in the number of devices to be connected, and allow extra ports for future expansion. Ports can be broadly classified into two categories: copper (LAN cable) ports and fiber optic ports.

If no fiber connections are needed and the site is relatively free of electrical noise or lightning, copper ports are sufficient. For long-distance transmission or noisy, lightning-prone environments, fiber ports are recommended.

Mounting Method

Typical mounting methods for industrial switching hubs include DIN rail mounting and wall mounting using screws. Magnetic mounting is another option, depending on the environment and application.

DIN rail mounting is the standard widely used in control panels, enabling efficient installation alongside other devices and allowing easy replacement or expansion. Wall mounting minimizes the effects of vibration and is suitable for installation outside control panels or in limited spaces. Magnetic mounting requires no tools, making installation quick and allowing easy repositioning during maintenance.

The best mounting method depends on the control panel layout, wiring design, and installation environment, so be sure to review these factors carefully in advance.

Environmental Resistance

To ensure stable operation, it is important to check that the industrial switching hub can withstand harsh conditions such as temperature variations, vibration, humidity, noise, water, and dust.

Environmental resistance is validated through various evaluations, including vibration and shock tests, EMC and electrostatic discharge tests, and power abnormality tests that simulate voltage fluctuations or momentary power outages. Products that have passed these tests can be considered highly reliable and expected to operate stably even in harsh environments such as factories or outdoor facilities.

When selecting a hub, it is recommended to check the specifications on the product page, including operating temperature range, dust and water resistance, humidity tolerance, and vibration/shock resistance standards.

Dual Power Supplies

Selecting an industrial switching hub that supports dual power supplies is highly recommended.

With only a single power supply, a power failure can shut down the hub and seriously affect connected devices. In a dual power supply system, the sub power supply acts as a backup to the main power supply, ensuring operation even if one supply fails.

This approach is known as redundancy, and dual power supplies are one form of redundancy.

Wide-Range Power Input

Wide-range DC input support is also important for ensuring stable, reliable operation of an industrial switching hub.

Models with a wide voltage input range (e.g., 8 to 35 VDC or 12 to 48 VDC) can flexibly accommodate standard 12 V, 24 V, and 48 V systems.

Wide-range DC input also allows stable operation despite voltage drops in long wiring runs or when using UPS or battery power.

When selecting a hub, it is important to check that the DC input range described in the specifications fully covers your power system. Also, it is crucial to check whether protection functions against reverse wiring and overvoltage are provided.

Auto MDI/MDI-X

Auto MDI/MDI-X automatically switches the ports of a switching hub between MDI and MDI-X.

As a premise, the sockets on a switching hub where LAN cables are connected are called ports. Ports are classified as MDI or MDI-X, depending on their pin assignments.

An RJ-45 port—the standard LAN cable connector—has an 8-pin structure and is classified as MDI or MDI-X depending on the assignment of transmit and receive signals.

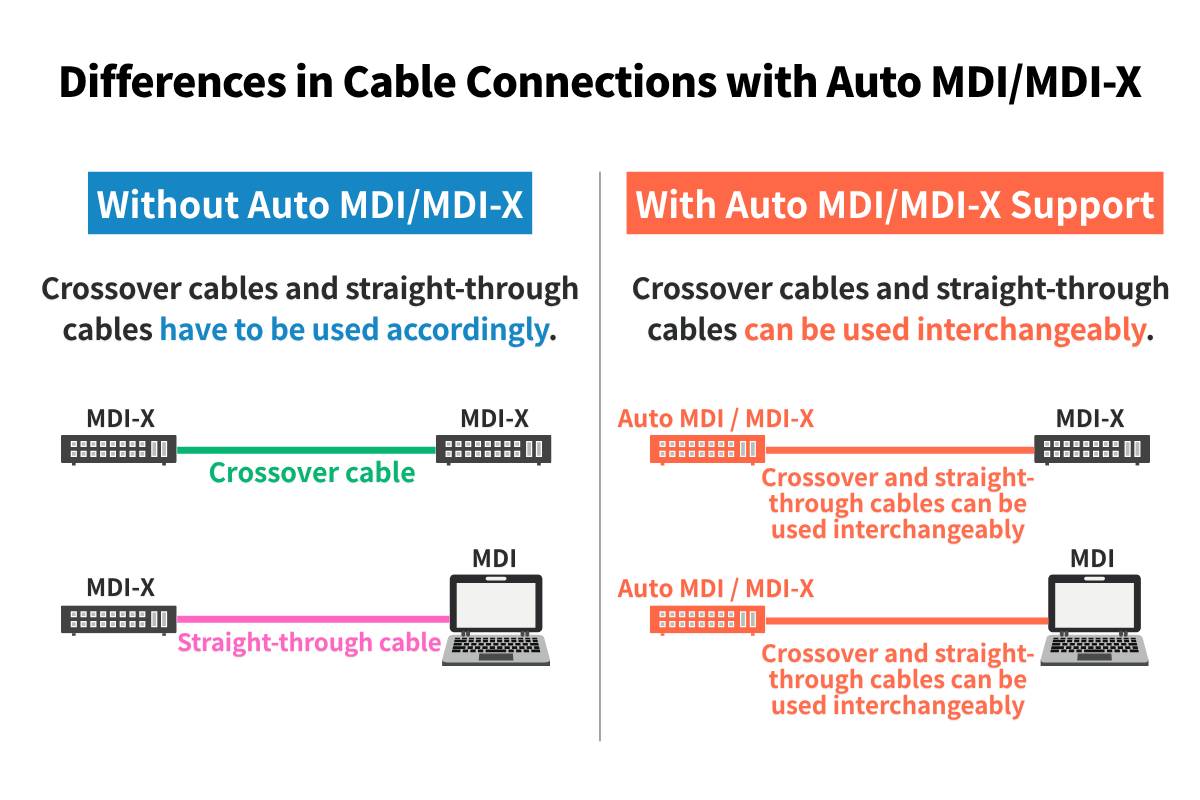

Differences in Cable Connections with Auto MDI/MDI-X

Without Auto MDI/MDI-X // Crossover cables and straight-through cables have to be used accordingly.

With Auto MDI/MDI-X Support // Crossover cables and straight-through cables can be used interchangeably.

Crossover and straight-through cables can be used interchangeably

MDI-to-MDI or MDI-X-to-MDI-X connections require a crossover cable, while MDI-to-MDI-X connections require a straight-through cable.

On hubs that do not support Auto MDI, the correct cable type for the port must be selected carefully. Using the wrong cable will prevent communication.

Hubs that support Auto MDI/MDI-X, however, detect and adjust port settings automatically, so there is no need to worry about the cable type.

Functionality: The Key Factor in Selecting an Industrial Switching Hub

When selecting a switching hub for industrial applications, such as factories or large-scale offices, it is important to select a model that offers comprehensive functionality.

Budget is always a factor, but the overriding priority should be reliability—ensuring stable operation and avoiding unplanned downtime.

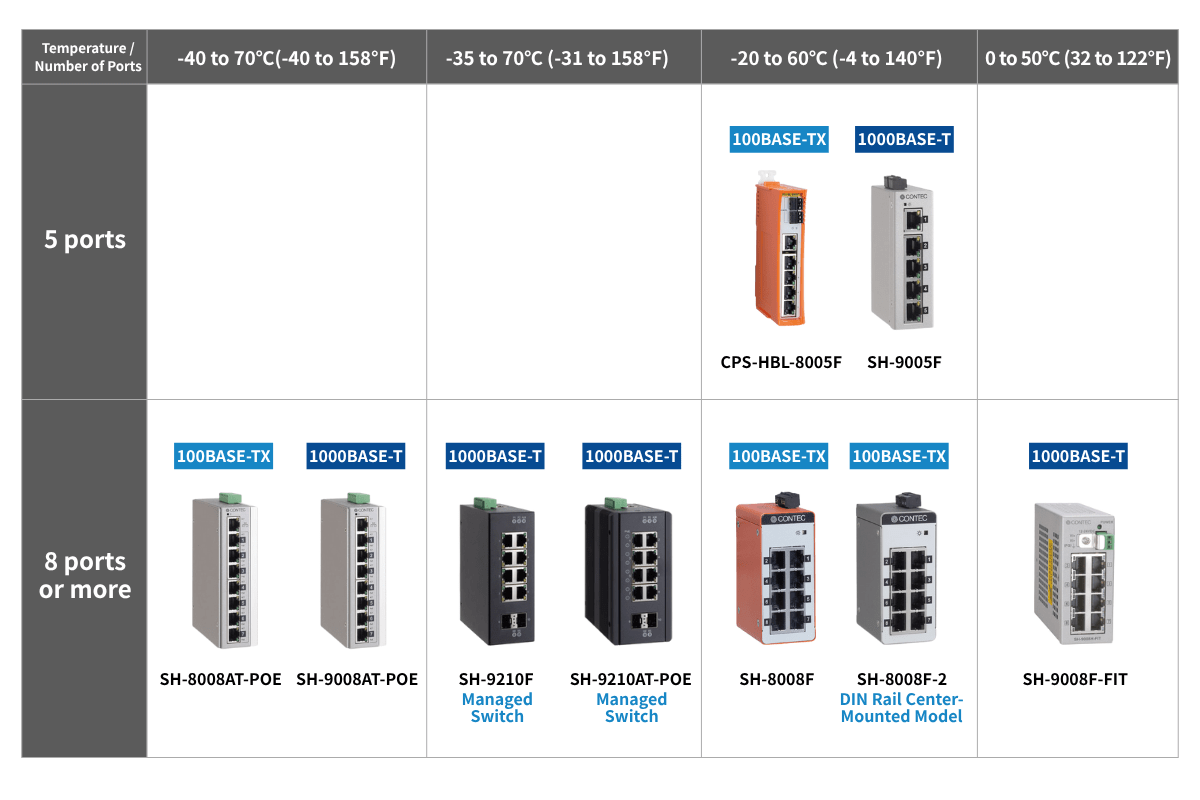

The following are representative Contec products that have the functions introduced in this article.

The CPS-HBL-8005F is a compact industrial switching hub equipped with five 10BASE-T/100BASE-TX ports.

The hub supports both Auto MDI/MDI-X and auto-negotiation, automatically detecting wiring and communication modes to prevent connection errors.

The hub is DIN rail mountable, allowing flexible installation in limited spaces such as control panels. The wide-range power input (8 to 35 VDC), dual power supplies, and reverse wiring protection circuit ensure stable operation even in harsh environments.

With an ambient operating temperature range of -20 to 60°C(4 to 140°F), the hub operates reliably across a broad set of site conditions.

The SH-8008F-2 offers the same core specifications as the SH-8008F. This industrial switching hub is equipped with eight 10BASE-T/100BASE-TX ports and can be operated within a temperature range of -20 to 60°C(-4 to 140°F).

A built-in reverse wiring protection circuit prevents issues caused by incorrect wiring. The centrally positioned DIN rail mount increases installation flexibility within control panels.

The wide-range power input (8 to 35 VDC) and dual power supplies ensure stable operation even in environments where devices with different voltage systems are in use.

The SH-9005F is an industrial switching hub equipped with five 1000BASE-T ports. The metal casing and fanless design support operation within an ambient operating temperature range of -20 to 60°C(-4 to 140°F).

With the supplied DIN rail and wall installation brackets, the hub can be installed easily on a 35 mm DIN rail or on the wall.

The wide-range power input (8 to 35 VDC) and dual power supplies ensure stable operation across diverse power conditions. The fanless design makes it suitable for quiet environments such as offices or control rooms where low noise is essential.

The SH-9008H-FIT is an industrial switching hub equipped with eight 1000BASE-T ports.

The hub supports jumbo frames, making it well-suited for networks that transfer large volumes of data. The metal casing and fanless design support operation within an ambient operating temperature range of 0 to 50°C(32 to 122°F).

The automatic power adjusting function can reduce power consumption by up to approximately 60% by automatically controlling the power to unused ports. Supporting 12 to 24 VDC power input and DIN rail mounting, the hub ensures stable operation in industrial settings.

Conclusion

Switching hubs, whether consumer or industrial, serve the same role of connecting devices to a network. The difference is that industrial switching hubs are designed for much harsher environments, making stability and downtime prevention top priorities in their selection.

That means carefully evaluating the types of connected devices, installation methods, and environmental conditions to select the product with the right functions.

Selecting an appropriate industrial switching hub ensures long-term, stable network operation in factories, large-scale offices, and various other sites.

Related Links

Back to Tech Blog Top

*

If you have already registered as a myCONTEC member and wish to receive eNewsletters, please change the settings from

"Edit Profile" after logging in.