System Overview

Create an AI-based error detection system easily and quickly by linking CONPROSYS with partner solutions.This makes it possible for customers to collect data, select analysis models, and register teaching (normal) data or additional teaching (accuracy improvement) data on their own.

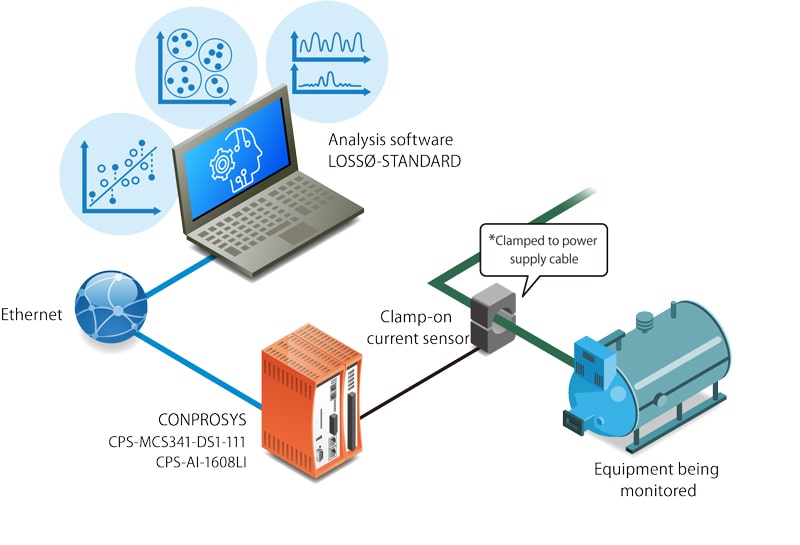

Systems Diagram

This system is just one example solution built with Contec’s CONPROSYS and NTC Corporation ’s LOSSØ-Standard, providing automatic detection solutions for the manufacturing industry.

CONPROSYS is used to collect data from external clamp-on current sensors installed on cables supplying power to equipment such as compressors, agitators, and cutting machines.

This collected data is used in the LOSSØ-Standard analysis model, with analysis initiated simply by specifying and registering a normal pattern. Users can also use the Remodel function to fine-tune the model on their own to improve accuracy.

Features

- Easy, quick collection of sensor data

Using CONPROSYS with current sensors enables data collection while also eliminating various tasks associated with analyzing sensor data. Using external clamp-on current sensors also simplifies installation on older equipment.

- Three optimal analysis models

LOSSØ-Standard includes standard models considered ideal for capturing current sensor characteristics. Customers can freely choose between these models for trial operations.

- Remodel function for improving accuracy

After registering a normal pattern, LOSSØ-Standard makes it easy to improve accuracy by registering additional normal data. Adding normal data is as easy as selecting the data from a graph.

Adopted Products

Learn More About CONPROSYS Controller Series

Related Links