The Insulation Deterioration Monitoring Module from CONPROSYS™ is a revolutionary product for measuring the insulation resistance of three-phase motors that otherwise cannot be measured without stopping the device. With the CONPROSYS™ Insulation Deterioration Monitoring Module, constant motor insulation deterioration monitoring is possible for three-phase motors, allowing for detection of possible signs of failure.

Insulation Deterioration Situations and Risks

Three-phase motors are commonly used in many moving mechanical devices such as machining equipment, water distribution pumps, and elevators. Depending on the operation time, the insulation penetration resistance of the stator coil may lead to declined performance, grounding faults, phase short circuits, layer short circuits, and other situations that may cause equipment failure, resulting in a dangerous situation. Failure of a device will not only stop the equipment but may also cause an accident that may put workers in grave danger.

Insulation deterioration event

Insulation Deterioration Monitoring Module Settings

The settings for the Insulation Deterioration Monitoring Module can be configured from a web browser by accessing the M2M Controller.

Basic settings including network environment settings, measurement modes exclusively used with the Insulation Deterioration Monitoring Module, power supply frequency, measurement range, and other settings can all be configured from a web browser.

For details, see the reference manual.

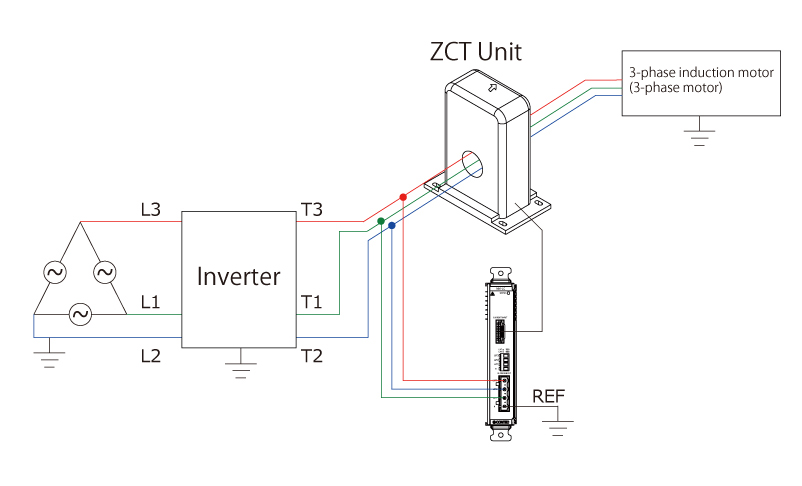

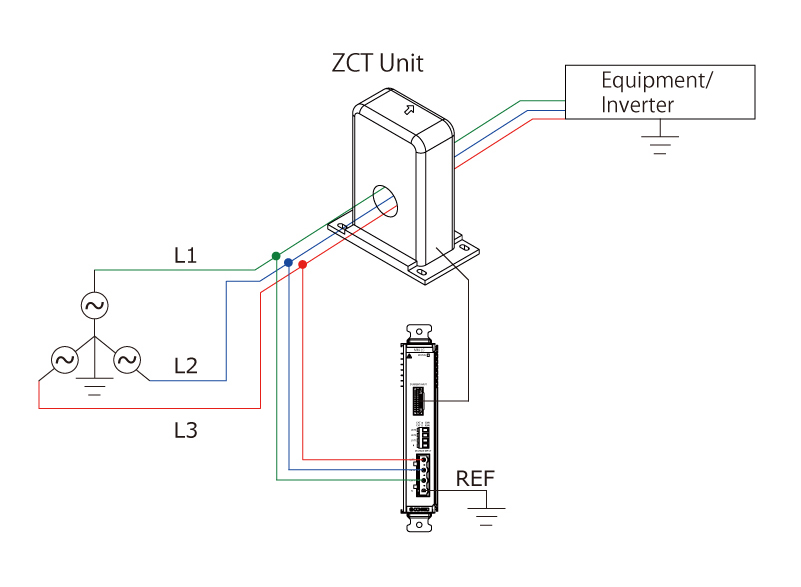

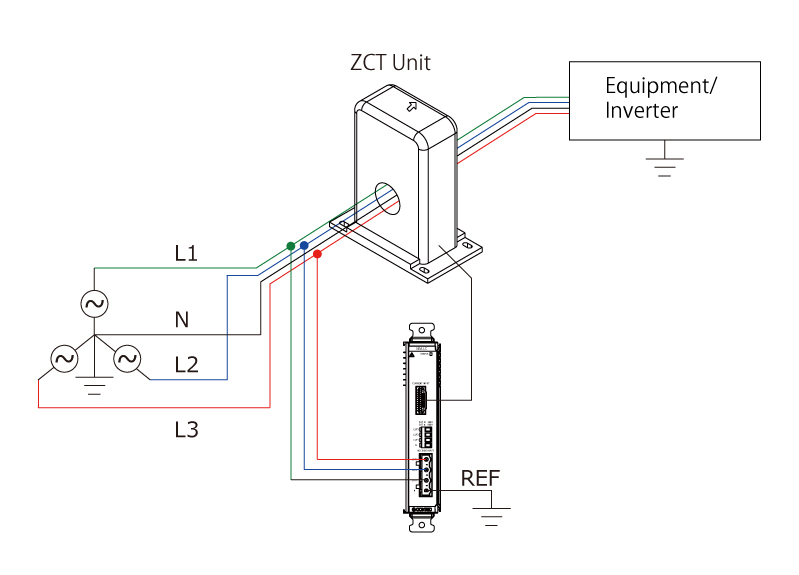

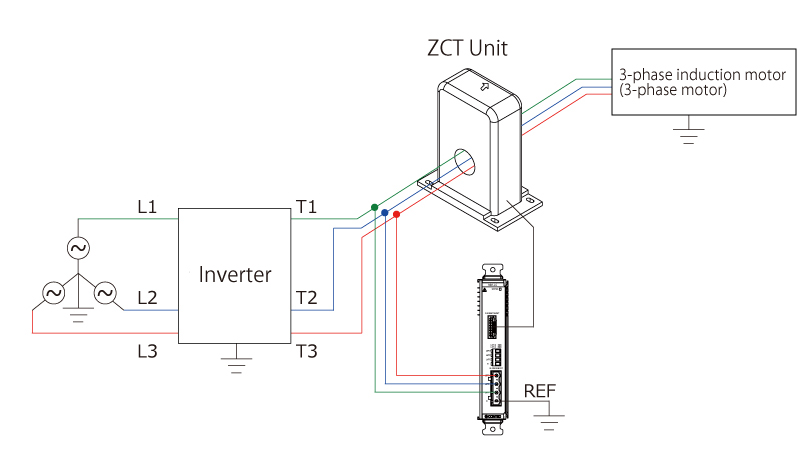

Connecting to a Three-Phase Motor

The Insulation Deterioration Monitoring Module is equipped with a ZCT sensor unit. Refer to the following diagrams to connect the module. For details, see the reference manual.

Inverter Powered by Three-phase Delta

(3-wire, three-phase corner-grounded System)

Click to enlarge

Click to enlarge

Three-phase Wye

(3-wire/4-wire, Three-phase Solidly-grounded Neutral System)

Three-phase Wye (3-wire, Three-phase Solidly-grounded Neutral System)

Click to enlarge

Click to enlarge

Three-phase Wye

(3-wire/4-wire, Three-phase Solidly-grounded Neutral System)

Three-phase Wye(4-wire, Three-phase Solidly-grounded Neutral System)

Click to enlarge

Click to enlarge

Inverter Powered by Three-phase Wye

(3-wire/4-wire, Three-phase Solidly-grounded Neutral System)

Click to enlarge

Click to enlarge

Free Sample Software

The monitoring screen and software are built using the CONPROSYS VTC script function and the CONPROSYS HMI screen creation function equipped with the M2M Controller.

Take advantage of a wide selection of sample script programs to begin use immediately.

Programs can also be customized as desired, including with notification emails at certain thresholds or with audible alerts.