Focusing on Sensor Interfaces: Fail-Proofing Your Choice of IoT Gateway (Sensors and IoT devices Column Part 2)

In the previous article, we looked at the various sensor output signal types, including digital output, pulse output, analog voltage output, and analog current output.

To ensure a proper connection between a sensor and an IoT device, it is essential to first look at the sensor interface.In this second “Sensors” and “IoT Device” column installment, we will look at how to select an IoT device by focusing on the sensor interface.

IoT Gateway Roles and Interfaces

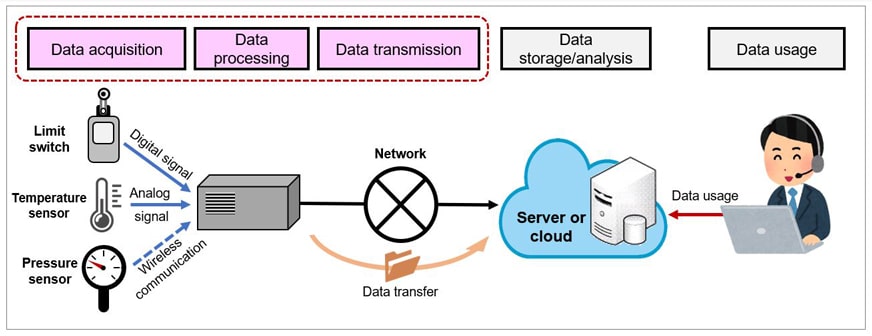

The Internet of Things (IoT) is being readily adopted in production factories and distribution systems. Adopting an IoT system means connecting sensors and other devices to a network to determine the physical quantity of things and changes in the environment. The sensors used at manufacturing sites or in social infrastructures, however, likely cannot be connected directly to a network.

To solve this, an IoT gateway device is used to relay data between a sensor and a computer used to process the data from the IoT system.

Roles of an IoT gateway

Roles of an IoT gateway

The types of sensors used include not only those that output digital or analog signals in response to changes in the physical quantities or the environment, but also those that can convert data within the sensor itself and transmit that data as communication. As such, there are a variety of interfaces used to connect the sensors, so selecting an appropriate measurement board or communication board—an IoT device—is essential.

ON/OFF Sensors (Digital Output)

Let’s take a look at motion sensors and photoelectric sensors. Motion sensors—sometimes referred to as human sensors—output two signal types: ON when a person is detected, and OFF when a person is not detected.In the same way, photoelectric sensors output two types of signals: ON when an object is detected, and OFF when an object is not detected.These are examples of digital output.Connecting a sensor that outputs this kind of digital ON/OFF signal to an IoT device requires a digital input interface for the signal input.

Learn more about digital I/O

Adding digital I/O functionality to a computer for use as an IoT gateway

Extending digital I/O functionality to a PLC or computer using remote I/O

Using independent IoT gateways

Sensors with Meaningful ON/OFF Counts (Counters)

Even among digital output sensors, however, there are different types, such as flow rate sensors that show the amount of liquid flow, and power meters that show the amount of electricity used.These sensors output a digital ON/OFF signal proportional to the detected amount.Instead of a device with just a digital input interface, using these sensors requires an IoT device that includes a counter function that automatically counts digital signals.

Using an IoT device with a counter input function is convenient even for use with a photoelectric sensor, as the photoelectric sensor can be used to count the number of products flowing on a belt conveyor.

Adding counter input functionality to a computer for use as an IoT gateway

Extending counter input functionality to a PLC or computer using remote I/O

Using independent IoT gateways

Sensors for Detecting Changes in Physical Quantities and the Environment (Analog Output)

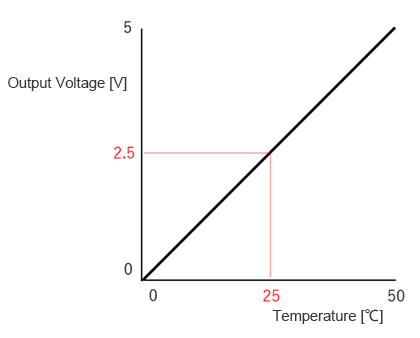

Instead of simply outputting an ON or OFF signal, many sensors output voltage or current according to changes in physical quantities or the environment.Let’s look at temperature sensors as an example.A temperature sensor with the following specifications will output 0 V at 0°C and 5 V at 50°C.

Connecting a sensor that outputs a voltage or current signal according to changes in physical quantities or the environment—such as temperature, humidity, distance, or pressure—to an IoT device requires an analog input interface for the signal input.

Example temperature sensor specifications

Example temperature sensor specifications

| Item |

Specification |

| Measurement range |

0 to 50°C |

| Output voltage |

0 to 5V |

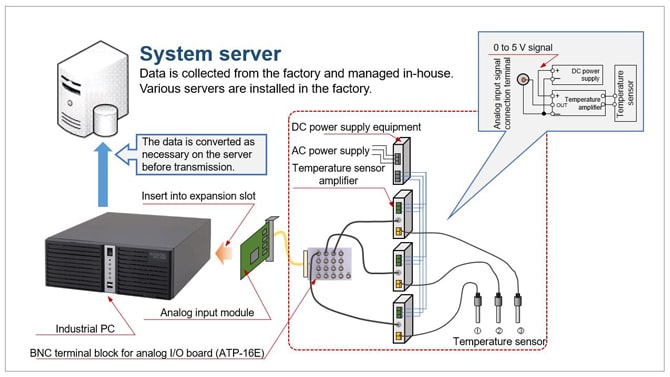

Computer used as an IoT gateway

Computer used as an IoT gateway

Learn more about analog inputs

Adding analog input functionality to a computer for use as an IoT gateway

Extending analog input functionality to a PLC or computer using remote I/O

Independently operated IoT gateway devices

Sensors that Convert Signals into Data for Communication Transmission (Communication Interfaces)

Some sensors include serial communication interfaces such as RS-232C and RS-485, and some even offer serial communication as well as additional communication protocols such as Modbus and PROFIBUS.When choosing an IoT gateway, first check the interfaces the device supports, such as for just sensors or communication as well.

Learn more about serial communication

Adding serial communication functionality to a computer for use as an IoT gateway

General-Purpose CONTEC Products with Special IoT Gateway Functionality

CONTEC has standardized not only the connection interfaces for on-site sensors and communication devices but also measured data processing methods and functions for converting data to a communication standard suitable for the host network. We are also developing a series of products with specialized IoT gateway functionality for use without the need for programming.

Computers are highly versatile and can perform complex control and advanced analysis processing. For use as an IoT gateway, however, the technical elements such as sensor connection methods, measurement data processing methods, and server communication methods must be organized and managed with programming.

If there is no need for special processing or advanced processing using a computer, a specialized IoT gateway product is recommended.

M2M Controller Series — Sensor Data Collection

With the M2M Controller Series, users can freely combine digital I/O, analog I/O, and serial communication (RS-232C/RS-485) I/O modules according to the sensors being used.

An integrated type for integrating the functions of the I/O module is also available.

M2M Gateway Series — PLC/CNC Data Collection

The M2M Gateway Series is an IoT gateway product compatible with multiple vendors and multiple interfaces, enabling communication with a variety of PLCs.One M2M Gateway Series device can communicate with several PLCs.The compatible PLC manufacturers and series devices are Mitsubishi Electric’s MELSEC series, Omron’s Sysmac, JTEKT’s TOYOPUC, Panasonic devices, and KEYENCE devices.

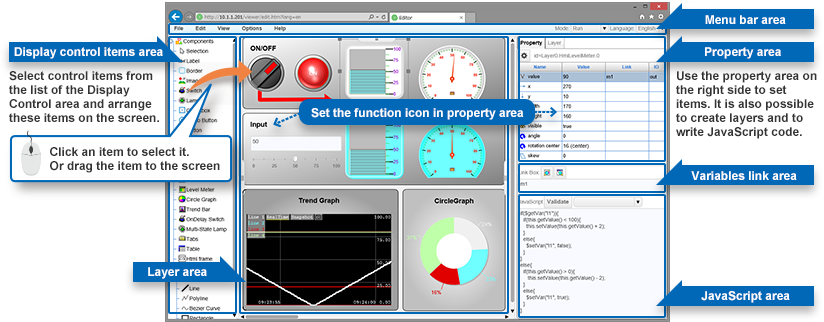

Convenient Scripting and HMI Functions from a Web Browser

The M2M Controller Series and M2M Gateway Series can incorporate a variety of processing tasks such as calculation, flow control, and character string operations through intuitive operations from a web browser.Data can be converted to industrial values before being sent to a server, and data can also be sent as average or integrated values, making it possible to reduce communication circuit loads and CPU loads on the server.

The M2M Controller Series and M2M Gateway Series are also equipped with a monitoring screen drawing/display function for data visualization.Graphs, lamps, and other display components can be organized and displayed directly from the browser through drag-and-drop operations.

Flexible IoT System Construction with CONTEC Products

There are a variety of sensor interfaces and communication standards used today.When choosing an IoT gateway, users must check whether the device supports specific interfaces and communication standards.

CONTEC offers a large number of expansion interface boards and USB devices as well as remote I/O products for using a computer as an IoT gateway.We also offer products with special IoT gateway functionality and flexible support for a variety of configurations.

This article has been an introduction to the roles and functions of IoT gateway devices.In the next installment, we will look in-depth at how to use sensor information by introducing various example usages.

Related Information

See All Blogs

*

If you have already registered as a myCONTEC member and wish to receive eNewsletters, please change the settings from

"Edit Profile" after logging in.