Contents

Interest in Remote I/O and Software PLCs Rising

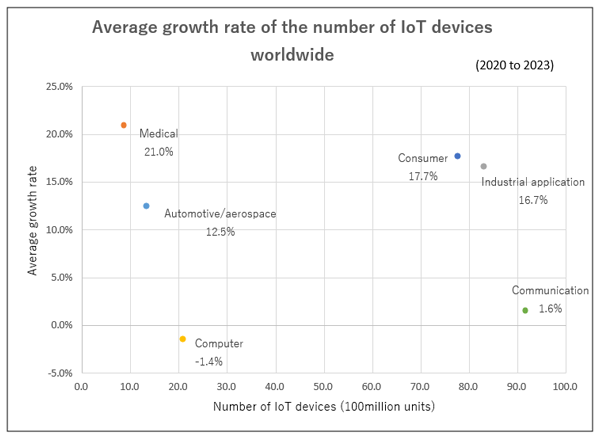

In recent years, the IoT device market has been experiencing rapid growth. According to the Information and Communications in Japan White Paper 2021 published by the Ministry of Internal Affairs and Communications, the number of IoT devices worldwide increased from 17.32 billion in 2016 to 25.3 billion in 2020, an increase of approximately 8 billion.

Source: Information and Communications in Japan White Paper 2021; Ministry of Internal Affairs and Communications

Source: Information and Communications in Japan White Paper 2021; Ministry of Internal Affairs and Communications

The telecommunications field (smartphones and telecommunication terminals) accounts for a large proportion of the number of devices, but the market is saturated, so growth is projected to be lower than in other fields.

Source: Calculated from the Information and Communications in Japan White Paper 2021; Ministry of Internal Affairs and Communications

Source: Calculated from the Information and Communications in Japan White Paper 2021; Ministry of Internal Affairs and Communications

Four areas with expected high growth rates can be identified: medical, consumer, industrial applications, and automotive/aerospace. In industrial applications, expectations are high for use of IoT to create smart factories, and it is commonly predicted that many devices will be introduced in the future.

However, as the number of IoT devices in factories increases, we are facing challenges such as securing installation sites, increased wiring for I/O signals, and more complicated maintenance after installation. This blog post introduces the theme of remote I/O for minimizing wiring and distributed control as one method to address these issues.

Challenges in I/O Signal Processing with Remote Locations

In control and measurement systems using PLCs and industrial PCs, many challenges arise during signal input and output with sensors and actuators in remote locations.

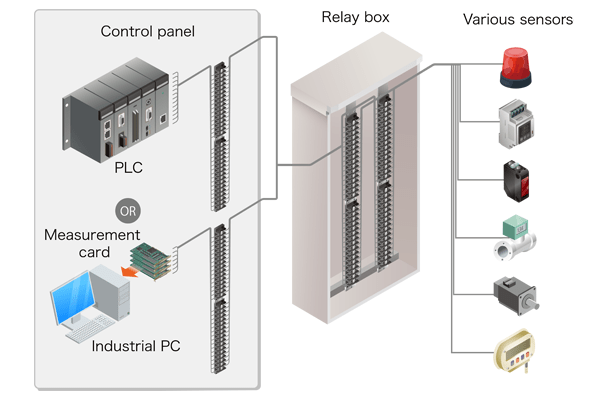

Example of I/O signal wiring in remote locations

Example of I/O signal wiring in remote locations

When connecting I/O signals between a controller and sensors in remote locations, signal wires must be wired for each sensor. The more input/output points there are, the longer the wiring distance, and the greater the number of wires that are required. In addition, the number of terminal blocks in the control panel increases, and the number of relay boxes and other facilities along long wiring routes also increases, so the cost of wiring work can increase rapidly.

From the standpoint of system reliability, wiring digital signals to a controller over long distances may cause malfunctions due to voltage drops, and transmitting analog signals over long distances may increase the impact of noise.

In cases such as these, many of the challenges can be solved if the input and output processing for sensors and actuators can be performed using a network instead of physical wiring.

What Is Remote I/O?

Remote I/O is a mechanism for input and output of measurement devices, input devices, controller, etc., in factories and other facilities using a network.

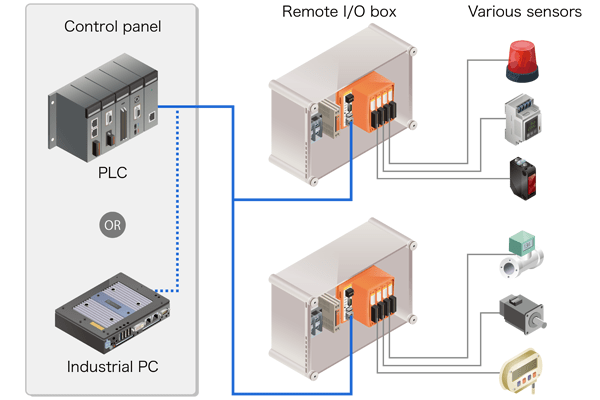

Example of I/O signal wiring using remote I/O

Example of I/O signal wiring using remote I/O

Since input and output is performed using a network, it is possible to minimize wiring, eliminating the need for complicated wiring and reducing the noise caused by transmitting data over long distances. It offers many other advantages, such as simplified system design and improved maintainability, and is used in various applications in factories where factory automation and IoT initiatives are underway.

However, some communication methods are not suitable for high-speed input and output, and some require safety measures in the event of a communication failure.

Types of wiring for remote I/O

The commonly used types of wiring for remote I/O can be divided into three main categories.

(1) Serial communication

Serial communication is based on communication standards such as RS-485 and CAN. It has been in use for a long time because many products can use general-purpose cables and it does not require special tools or advanced skills. Typical communication methods include CC-Link, DeviceNet, Modbus-RTU, etc. In some cases, dedicated cables are specified by the manufacturer to ensure communication quality.

(2) Ethernet communication

Ethernet communication is based on communication technology that is widely used for the Internet and office networks. It has the advantage that general-purpose cables and network equipment used in general network construction, such as LAN cables, optical cables, and switching HUBs, can be used, and that relatively high-speed communication can be easily achieved. Typical communication methods include Ethernet/IP, EtherCAT, and Modbus TCP.

Contec has released the CONPROSYS™ nano series as a remote I/O product that supports Modbus communication.

The CPSL-08P1EN IO-Link master with 8-channel IO-Link port (Class A) is also available. It can be used for remote I/O that can meet needs to be IP67-grade dustproof and waterproof.

(3) Wireless communication

Remote I/O using wireless communication methods is based on Wi-Fi or sub-GHz band wireless communication technology. Wireless communication offers many advantages, such as eliminating the need for communication cables between terminals, which reduces construction costs, and allowing for communication with moving equipment.

Contec has released the wireless I/O series, which allows easy use of Sub-1GHz band wireless communications.

Use of Software PLCs to Compensate for the Shortcomings of Remote I/O

As explained above, some remote I/O communication methods are not suitable for high-speed input and output, with some even requiring safety measures in the event of communication failures. If signal processing can be performed in the local terminal during remote I/O, high-speed response and safety measures for processing control are possible.

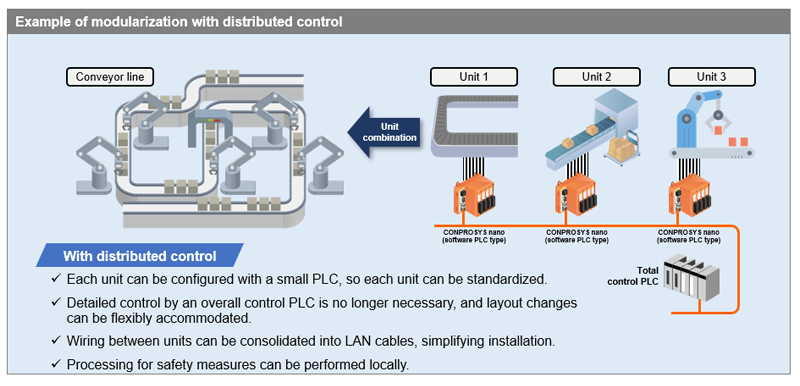

In addition, using distributed control to configure equipment in large facilities allows for modularization of equipment by dividing it into units. This can help reduce design man-hours and installation costs.

The CONPROSYS™ nano series also includes a programmable remote I/O coupler unit with software PLC functions. This product is an I/O coupler unit with built-in software PLC functions compliant with the IEC 61131-3 international standard, and can perform signal processing within the local unit while allowing for remote I/O. This allows for the construction of systems that take signal processing speed and distributed control into consideration.

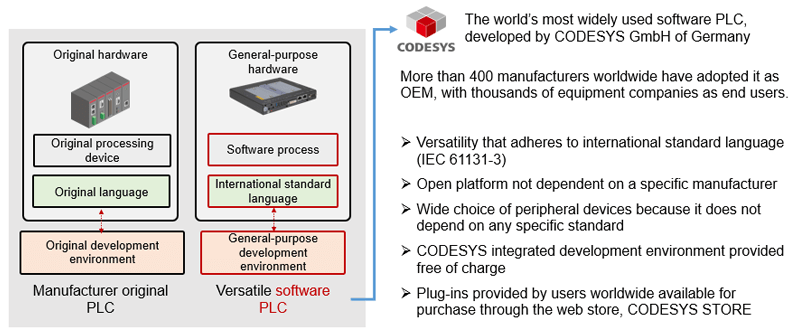

What Is a Software PLC?

A PLC is a controller that is mainly used to control equipment in factories. PLCs have been in use for a long time, but they continue to evolve and still play a part in IoT in factories and robot control.

Most PLCs from controller manufacturers consist of the hardware and PLC software that are unique to that manufacturer. In other words, hardware and software are sold as a single unit. Porting software running on one manufacturer’s PLC to a different manufacturer’s PLC is a major task that requires a very high level of skill.

Software PLCs, on the other hand, are licensed as stand-alone software and are separate from the hardware. They can be installed and used on any hardware, such as an industrial PC or Raspberry Pi. In other words, hardware that best suits a given application can also be used as a PLC.

What is software PLC CODESYS?

CODESYS is a software PLC developed by German company CODESYS GmbH, which has garnered a lot of attention as smart factories and IoT ideas have spread around the world, and more than 400 companies worldwide now use CODESYS.

In addition to the nano series with built-in CODESYS, Contec has also released the CONPROSYS™ PAC series with HMI web monitoring and fieldbus master functions.

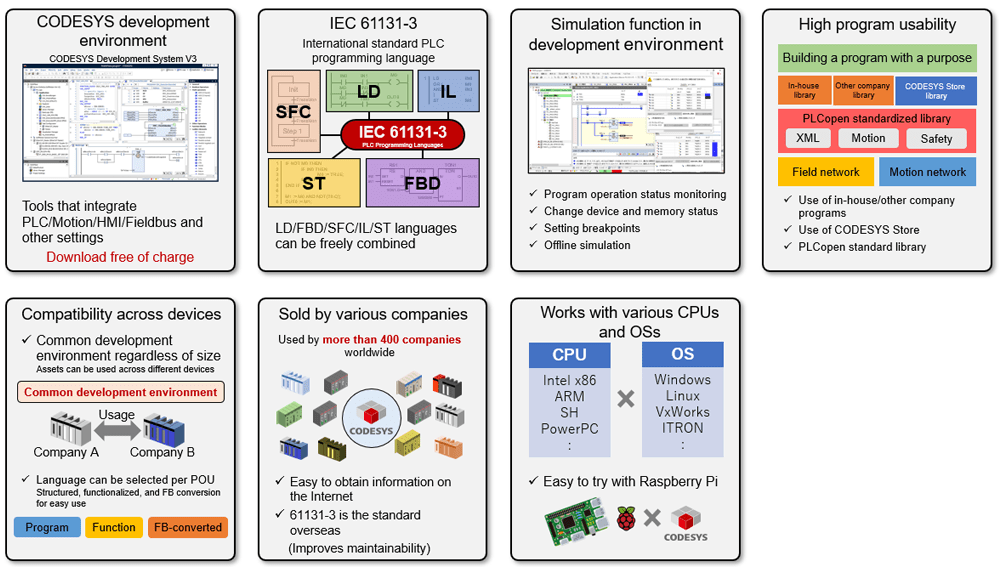

CODESYS features

CODESYS, a software PLC, consists of a development environment (IDE) for developing programs and an execution environment (Runtime) for running programs.

The CODESYS integrated development environment used to develop programs is provided free of charge, which lowers the cost of introduction, and is also easy to learn.

Since the CODESYS runtime works with various CPUs and OSs, different types of controllers are available from a range of manufacturers. A runtime that runs on Raspberry Pi is also available, and the free version can run for two hours after startup, making it easy to try programming before committing to the system.

Remote I/O Case Study

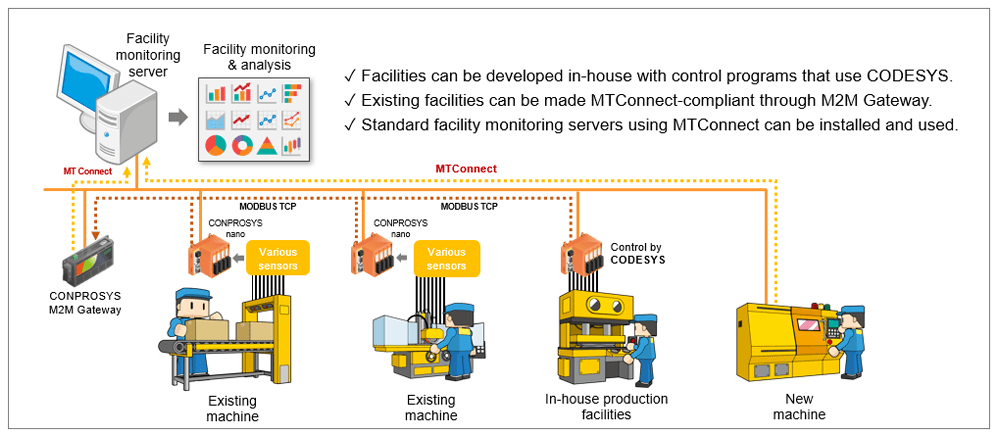

The following case study is an example of using remote I/O to monitor a factory facility that is not IoT-compatible.

Some of the latest equipment easily supports IoT because it is Internet-compatible and can be connected to IoT systems. However, supporting existing equipment that has been in use for a long time is generally considered difficult, and the cost to convert them for Internet compatibility through in-house development can be high.

Monitoring non-IoT-compatible facilities in a factory

Monitoring non-IoT-compatible facilities in a factory

In this case study, by adding sensors to equipment without PLCs and utilizing CONPROSYS™ nano series for signal input, equipment can be successfully converted to IoT with reduced installation costs.

In addition to the CONPROSYS™ nano series, the CONPROSYS™ M2M Gateway is used to easily connect to existing PLCs to support IoT.

Conclusions

In this blog post, we explained wiring minimization and distributed control by remote I/O.

Digital transformation (DX) in the industrial field is progressing, and with the increase of IoT devices in factories, new issues are coming to light.

- As the number of I/O signals increases, the control panels that house those signals become larger.

- Large amounts of wiring work to remote locations increases costs.

- After installation, it is difficult to add signals for functional improvement or to maintain and manage.

These are some of the issues that must be addressed.

Appropriate use of remote I/O and distributed control offers the following advantages.

- The amount of wiring and wiring work can be reduced.

- Expansion when adding additional sensors or I/O devices is easier.

- In addition, distributed control allows for signal processing and modularization.

IoT and DX initiatives are key to corporate growth. The CONPROSYS™ nano series offers the functionality required for IoT that is affordable even for IoT initiatives with limited budgets. Why not consider remote I/O as part of how your business uses digital technology?

Drawing on our time-proven electronics manufacturing know-how and the latest cloud service technologies, Contec offers products that customers can feel confident about introducing to their sites.

Related Contents

See all blogs