Remote I/O System for IoT

CONPROSYS™ nano Series

Remote I/O devices for digitizing interspersed local devices.

CONPROSYS nano is easy to use and features excellent cost performance, accelerating the digital transformation of industrial systems.

Select from Two Types According to the Application and System Configuration

Remote I/O Coupler Units (Slave Type)

A wide range of I/O modules can be used as remote I/O for communication devices which include Modbus master functions.

This library software provides commands to Contec measurement control devices via an OS standard API.

Types of Remote I/O Coupler Units

Functions Included with Remote I/O Coupler Units

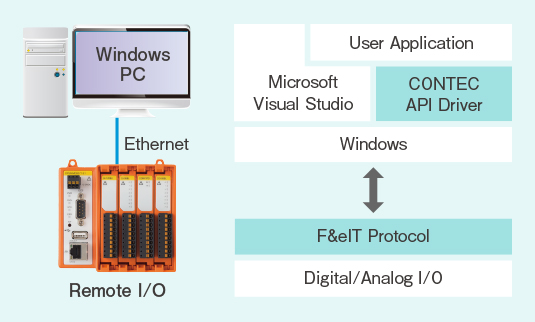

Windows driver (Win32 API functions)

Use the driver library that can be downloaded for free from the Contec HP to create digital or analog signal I/O that is connected to the remote I/O in the same way as a program for a Contec expansion card. Linux drivers are also provided for free.

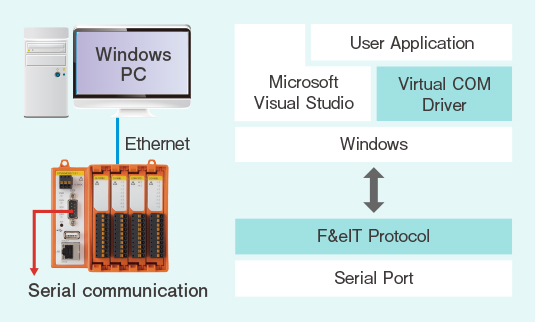

Virtual COM functions

Use the virtual COM drivers that can be downloaded for free from the Contec HP to access the remote I/O serial port as a Windows COM port.

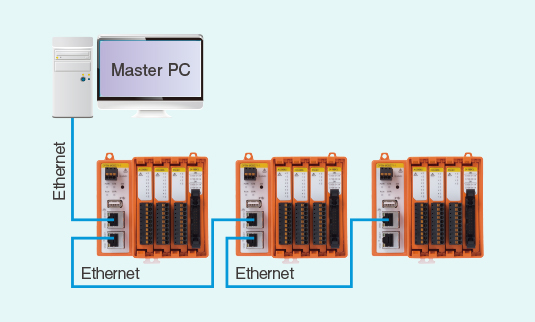

Daisy chain connections

When there are multiple remote I/O configured on the network, the remote I/O terminals can be connected in a daisy chain, eliminating the need for a network branching hub.

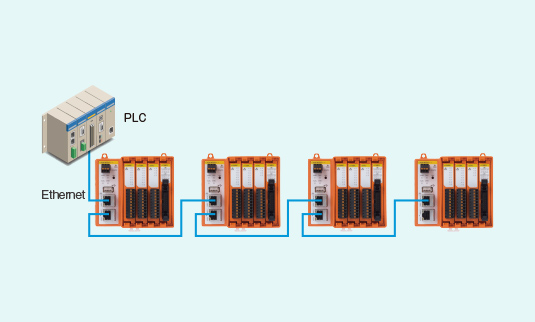

Remote I/O using Modbus

An industry standard Modbus protocol is included, allowing the I/O module of devices that support Modbus master functions to be used as remote I/O.

Creating Programs Using the Windows Drivers

Click here for the creation procedure

Creating Programs Using the Windows Drivers

Download and install the driver software.

Use the Device Manager and manually install the drivers.

Use the Contec Device Utility and check the device names.

Start the diagnosis program and check the operation of each device.

Visual Create a program from Visual Studio using the API functions.

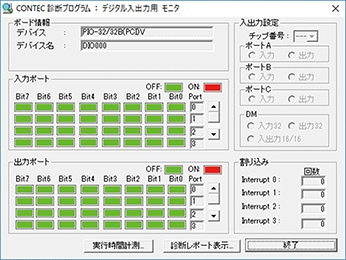

Digital I/O check screen

Digital I/O check screen

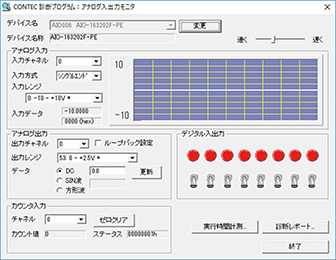

Analog I/O check screen

Analog I/O check screen

Programmable Remote I/O Coupler Units (Software PLC Type)

CODESYS runtime that complies with IEC 61131-3 is built-in, allowing the use of a wide range of I/O modules.

CODESYS runtime is built-in. This makes it possible to execute IEC-61131-3-compliant PLC programs that were developed in the CODESYS integrated development environment.

Supported PLC Languages

A total of 6 languages are supported: 5 IEC 61131-3-compliant languages (ST, LD, FBD, SFC, and IL) and CFC. The object-oriented programming defined in the third edition of IEC 61131-3 is also supported.

- ST (Structured Text)

- LD (Ladder)

- FBD (Function Block Diagram)

- SFC (Sequential Function Chart)

- IL (Instruction List)

- CFC (Continuous Function Chart)

Types of Programmable Remote I/O Coupler Units

Functions Included with Programmable Remote I/O Coupler Units

I/O expansion using remote I/O

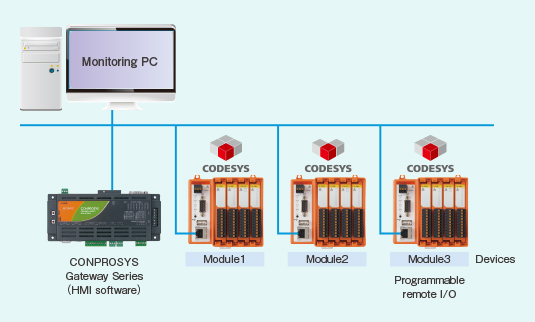

By using the CODESYS Modbus TCP master functions and connecting to the remote I/O-only couplers via the network and increasing the number of I/O points, it is possible to place the necessary I/O in the necessary locations and optimize the cable connections.

Module configuration using distributed control

In a system with a modular design, control of each unit with CODESYS allows a modular configuration that includes the wiring and increases the degree of freedom in system design.

Creating Programs Using the CODESYS Development Environment

Click here for the creation procedure

Creating Programs Using the CODESYS Development Environment

Download the CODESYS development environment from the 「

CODESYS Store

」(free) and install it.

Using the CODESYS development environment Package Manager, select the nano Series CODESYS package.

Connect the PC and CONPRSYS nano using an Ethernet cable.

-

Check the IP addresses of each device in the network settings.

Example: Coupler unit “10.1.1.101”, PC “10.1.1.200”

-

Perform programming using the CODESYS development environment.

Create a new project.

I/Add the I/O module configuration.

I/Define the I/O variables for the I/O modules.

Create a PLC program using an IEC-61161-3 language.

Execute [Build] from the development environment menu.

Download the target program.

Use debugging to check the program operation.

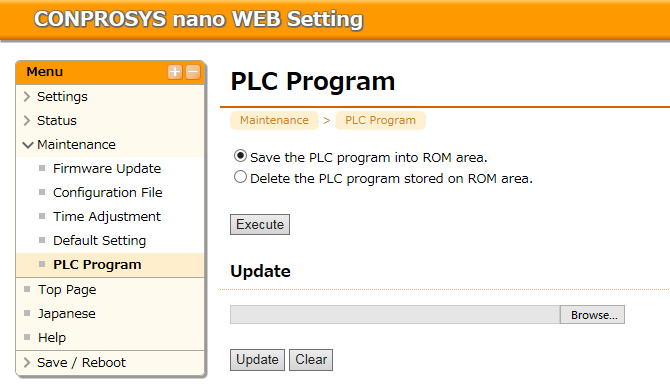

Save the completed PLC program to ROM.

ROM save screen (Web setting screen)

ROM save screen (Web setting screen)

Device window

ST Editor window

Seminar Textbook

For hands-on seminar of the CONPROSYS series [10MB]

Free Download