The following blog entry is a re-edited version of the indexPro iP-special (PR article) which was posted in November 2023, with original Contec additions including an explanation of the communication protocols that appear in that article.

Contec continues to provide expansion cards for measurement control that support a wide range of sensors and field devices, and has led the PC-based electronic measurement and FA control market for more than 30 years. In the field of photovoltaic generation and infrastructure equipment, Contec has delivered remote monitoring systems to more than 20,000 sites. Based on these development technologies and sales achievements, in 2015 we released CONPROSYS™, which was developed in pursuit of simplicity, convenience, and ease-of-use, for the M2M/IoT market. Subsequently we added and reviewed functions in order to meet the needs of a wide variety of users, and carried out firmware development of network functions and standardized IoT functions for a broader market.

Contents

CONPROSYS IoT Gateway Series That Can Be Selected According to the Application

The Internet of Things (IoT) market is transitioning from the introductory stage (innovators and early adopters) to the expansion period (majority). As nearly all companies are promoting digital transformation (DX), IoT concepts are steadily spreading throughout all industries. Contec follows changes in this market together with the users, and has expanded the CONPROSYS product lineup and provided the functions necessary for creating IoT systems.

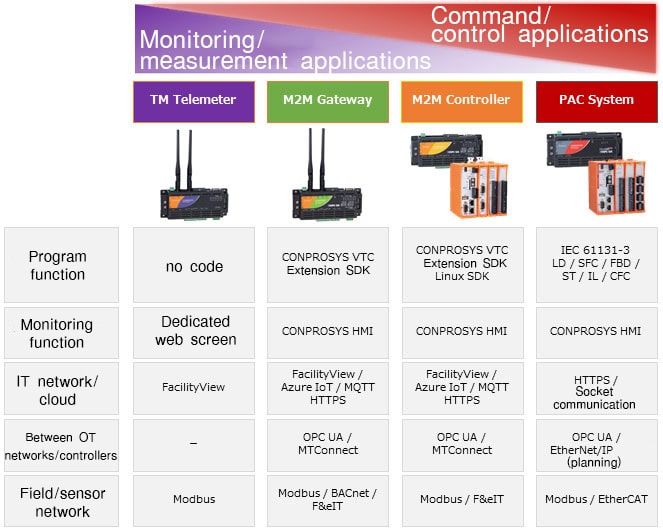

We offer a lineup of four types ranging from telemeters (TM Telemeter) that can perform monitoring and measurement on a non-programming basis to programmable automation controllers (PAC System) that include a software programmable logic controller (PLC) which can perform commands and control programs using PLC language.

The applications and functions of CONPROSYS IoT gateway products are as shown below.

IoT Functions That Are Advanced by Firmware Updates

CONPROSYS IoT gateways support the MTConnect, OPC UA, Modbus, and MQTT global standard field network/IoT communication protocols.

These functions are installed as firmware in the computer devices, and we provide a mechanism that allows the users to update the firmware themselves. Since the start of sales, we have repeatedly carried out numerous additions and improvements to functions based on requests from the users, and have created products that truly provide simplicity, convenience, and ease-of-use.

CONPROSYS IoT gateways automatically retry data transmission when the data transmission process was not completed due to some kind of communication interference. Even when communication interference is prolonged, a function accumulates the data transmission processes in multiple queues, and restarts the incomplete data transmission processes when the communication interference ends. System designers have expressed great gratitude for the standard-equipped functions that prevent data loss due to communication interference.

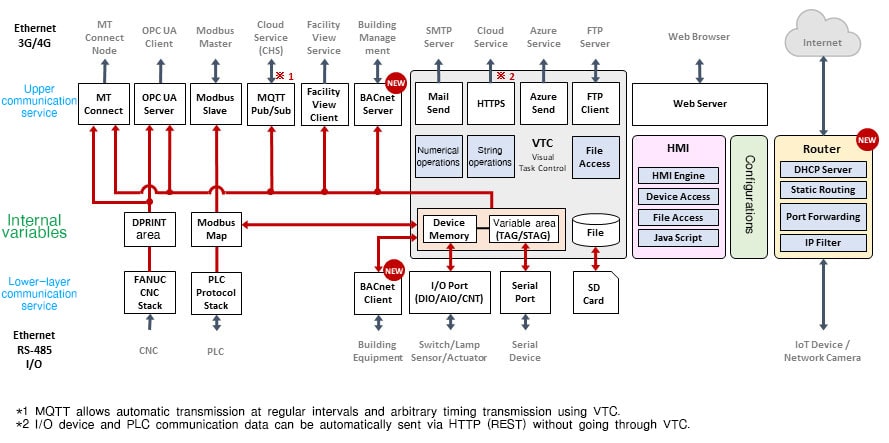

A block diagram of the M2M Gateway is as shown below.

Block diagram of IoT gateway functions

Block diagram of IoT gateway functions

What Is MQTT?

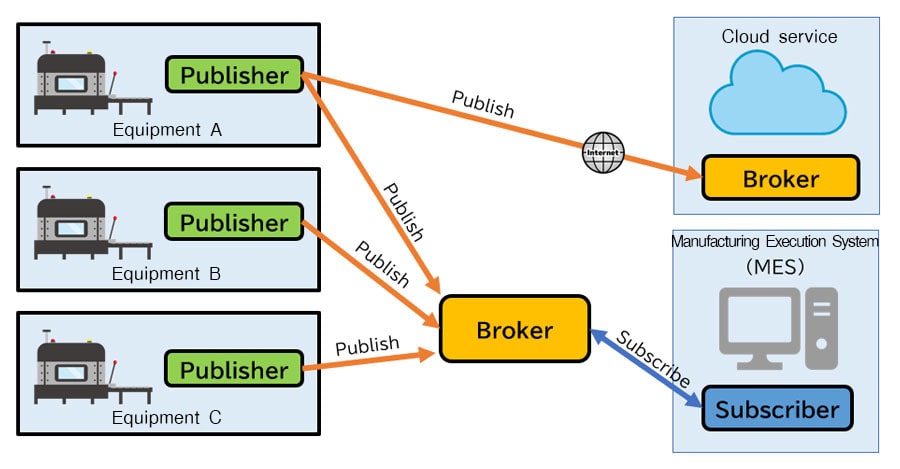

MQTT is a protocol that was proposed by members of IBM and Eurotech in 1999. MQTT communication was developed to temporarily hold the data sent by the transmission side in a data area, while allowing communication to move on to the next process without waiting for the process on the receiving side to be completed.

This communication protocol has gained much attention in the IoT field because of its characteristics that minimize network bandwidth and device resources while ensuring a certain level of reliability.

Example of MQTT communication configuration

Example of MQTT communication configuration

Features of the MQTT Protocol

- Simple protocol

Because this is a light protocol with an extremely small minimum header size of 2 bytes, it can be used on devices which have strict restrictions on memory and operation speed, and in narrow-bandwidth communication environments.

- Scalable

Because few resources are required for installing a communication environment, it can be installed in all kinds of devices from compact IoT devices to high-performance terminals, and allows the construction of highly flexible systems.

- Reliability

MQTT allows the installation of mechanisms that enable communication according to the level even in unstable communication environments. Examples include functions which shorten the time required for an IoT device to reconnect, and functions which allow communication reachability to be set.

MQTT Protocol Security

When constructing an IoT system using MQTT, security is an important element for protection against a wide range of attacks and threats. It is recommended that ID, authentication, and permission be installed between the client and broker using SSL certificates and passwords.

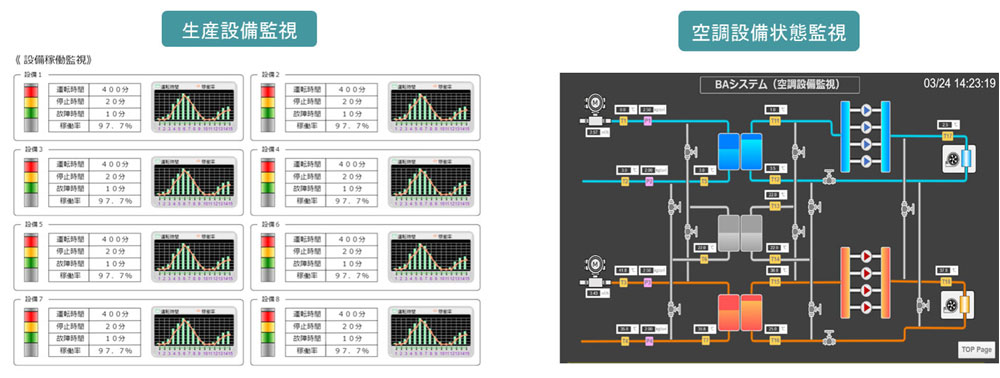

New Support for BACnet Communications

CONPROSYS IoT gateways now include new BACnet server functions and client functions, as well as router functions, delivering advances that allow them to be used for incorporating IoT in building facilities.

Equipped with BACnet Communication Functions

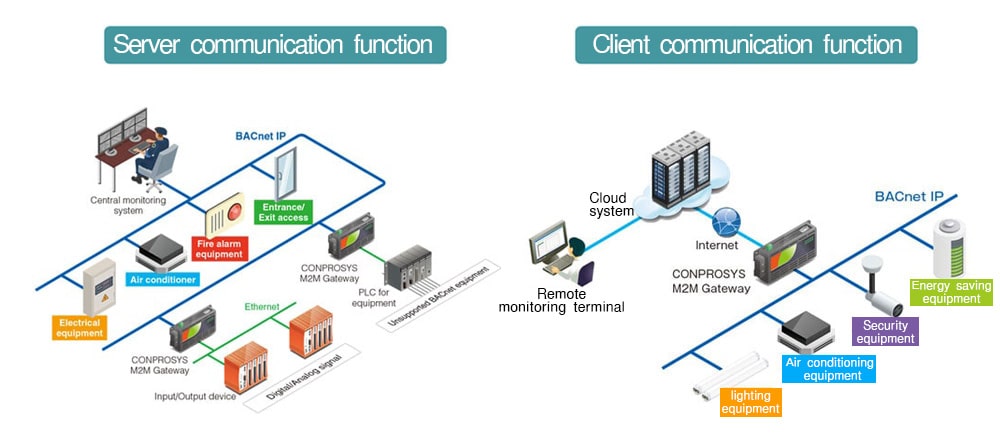

BACnet is a communication protocol standard for intelligent building networks. It allows the construction of systems for connecting and monitoring all devices via a common interface even when the products are from different manufacturers. It is used in fields including air conditioning equipment, lighting systems, electrical equipment, security and disaster-prevention equipment, and elevators. The CONPROSYS M2M Gateway supports the BACnet IP protocol, and includes server communication functions and client communication functions.

Server communication functions

These functions provide IoT gateway internal information to the BACnet client using BACnet object types. This enables equipment and sensors that do not support BACnet to be integrated into a BACnet communication building management system.

Client communication functions

These functions collect information from building equipment devices (BACnet server) and provide the information to a higher-level system after first converting it to MQTT or another different communication protocol. This allows the construction of systems for integrated remote monitoring of building equipment information interspersed across multiple locations via the cloud. It is also possible to convert building equipment devices that support BACnet to OPC UA, MTConnect, or other communication in order to integrate the factory equipment systems.

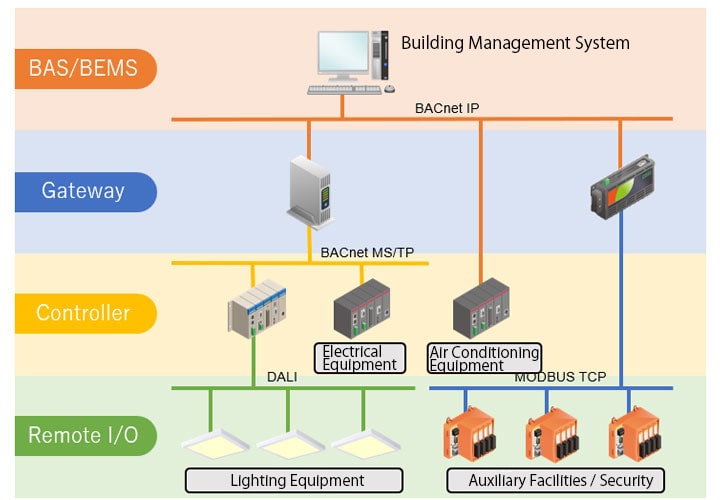

What Is BACnet?

Building Automation and Control Network (BACnet) is a communication protocol standard for building networks. It is used for control of air conditioning, lighting, electrical power, security, disaster-prevention, elevators, and other equipment in a building. The policy was decided at a meeting of various organizations related to building automation (BA) systems in 1987. Based on the ANSI/ASHRAE Standard 135-1995 that was established in 1995 by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), BACnet was prescribed as a BA system protocol in the international standard ISO 16484-5 in 2003.

In Japan, the Japan standards (IEIEJp, IEIEJp-A) which expand the standard to Japanese specifications were formulated by the Institute of Electrical Installation Engineers of Japan (IEIEJ). As a result, there are now three protocols including the standard ASHRAE BACnet.

BACnet includes the BACnet IP protocol for communication of BACnet services via Ethernet, and the BACnet MS/TP protocol that uses EIA-485 (RS-485) on the data transmission physical layer.

Example of building management system configuration

Example of building management system configuration

The use of the BACnet protocol eliminates the need for interfaces with manufacturer original specifications for the equipment and systems that are currently in use. This allows the construction of a system for connection and monitoring among devices from different manufacturers via a common BACnet interface.

Data Linking Using OPC UA Server and MTConnect Communication

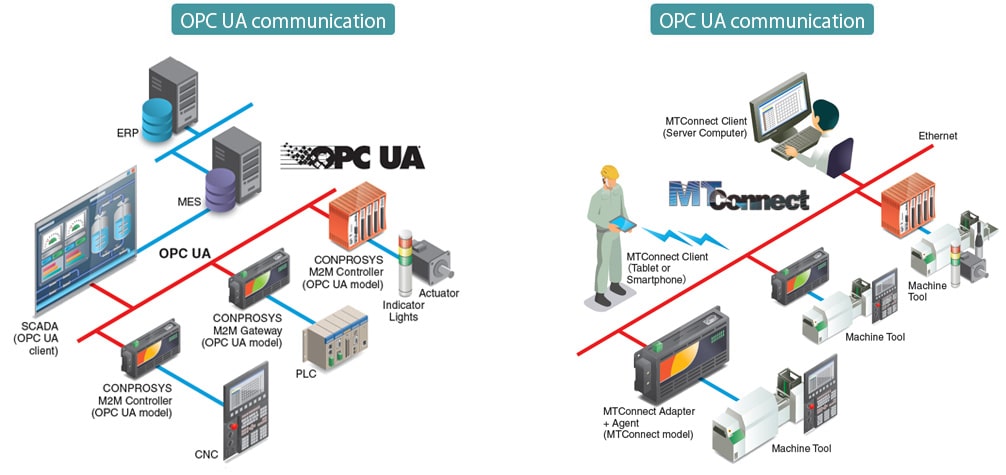

The CONPROSYS IoT gateways include OPC UA server functions, and can easily visualize collected data using supervisory control and data acquisition (SCADA) and business intelligence (BI) tools. They also include the MTConnect Adapter communication protocol for machine tools, enabling access from client software that supports MTConnect.

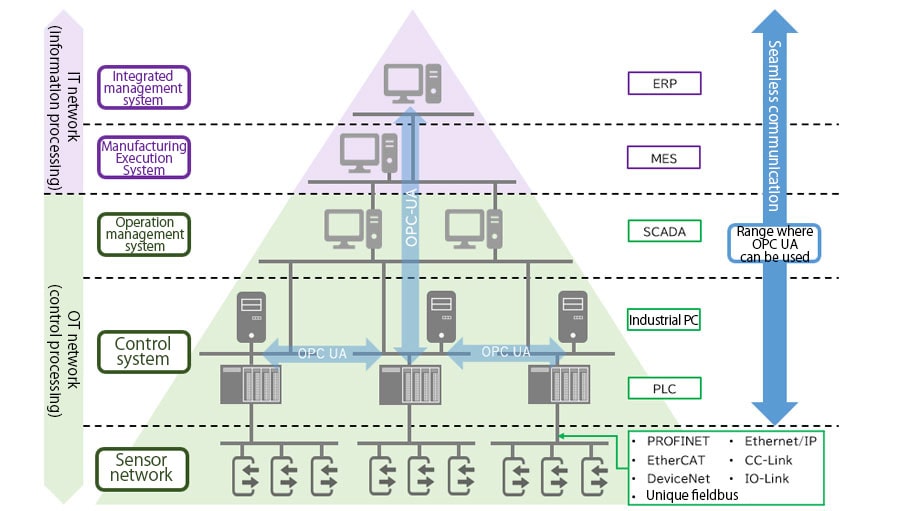

What Is OPC UA?

OPC Unified Architecture (OPC UA) is an open international standard that was formulated for performing safe and reliable data exchange in industries such as industrial automation of production factories, plant equipment, and other facilities. The standard was announced by the OPC Foundation in 2008, and IEC 62541 was subsequently created as an international standard.

It is highly consistent with the PLC international standard IEC 61131-3, and can easily connect manufacturing workplace (FA) information with a higher-level monitoring control system (SCADA) or production management system (MES) while maintaining reliability. As a result, it has been widely adopted by industries such as the PackML communication standard for packaging equipment (ANSI/ISA-TR88), the EUROMAP communication standard for injection molding equipment, the umati communication standard for machine tools, and other standards. The German Mechanical Engineering Industry Association (VDMA) is currently formulating the OPC UA for Machinery communication standard which integrates the standards that have been created in each industry and serves as a base for all machinery and equipment.

Example of system configuration using OPC UA

Example of system configuration using OPC UA

Features of OPC UA

- Scalability

Using OPC UA makes it possible to construct unified and scalable systems ranging from embedded systems to mainframes.

- Interconnectivity

Previously, original manufacturer communication standards were used for industrial equipment and control equipment, and there were cases when linking within the overall system was difficult. With OPC UA, it is possible to seamlessly connect from controllers within the factory to monitoring systems, production management systems, and other systems.

- Security

Security countermeasures for plants and factory equipment have become an issue in recent years. Because OPC UA uses a secure channel to ensure the security of messages between the OPC UA server and client, it can easily provide secure communication between equipment.

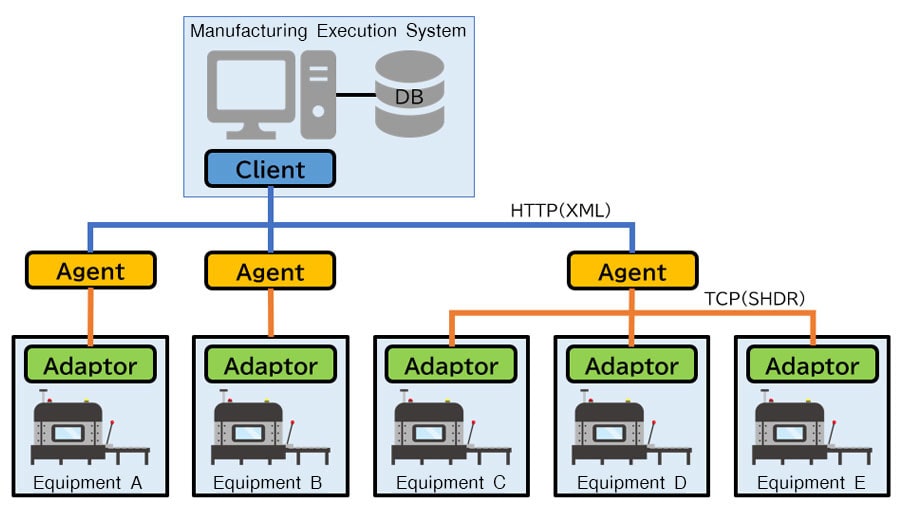

What Is MTConnect?

MTConnect is a communication protocol designed for machine tools that was standardized by the MTConnect Institute. It is a protocol that was formulated to enhance device and application data acquisition functions and reduce integration costs. This standard has already been adopted by a large number of major manufacturers centering on the United States, and is gaining attention as a future standard.

Example of system configuration using MTConnect

Example of system configuration using MTConnect

Features of MTConnect

- Open protocol

Previously, when using machine tools from multiple companies, it was necessary to develop software to match the original standard of each manufacturer. However, because MTConnect is an open protocol that uses standard Internet technologies HTTP and XML, conversion software can be installed relatively easily.

- Royalty-free

MTConnect is royalty-free, and therefore it is not necessary to pay license fees to the MTConnect Institute. Companies which agree to the MTConnect license agreement can integrate MTConnect into their products.

- Common data structure

MTConnect prescribes the data structure of each data type for various data acquired from machine tools (main axis load, axis speed, alarms, etc.). User companies can compare and collect data of the same type without being troubled by the data structures, even when connecting equipment from different machine tool manufacturers.

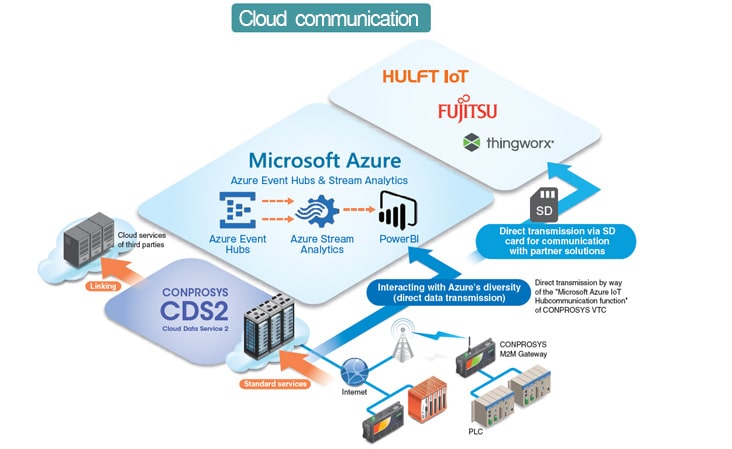

Flexible Support for SCADA and Cloud Services from Various Companies

The MQTT, HTTPS, TCP, and other communication functions provide excellent connectivity not only with our company’s own FacilityView cloud service and CONPROSYS HMI System (CHS) SCADA software, but also with the cloud services of various other companies.

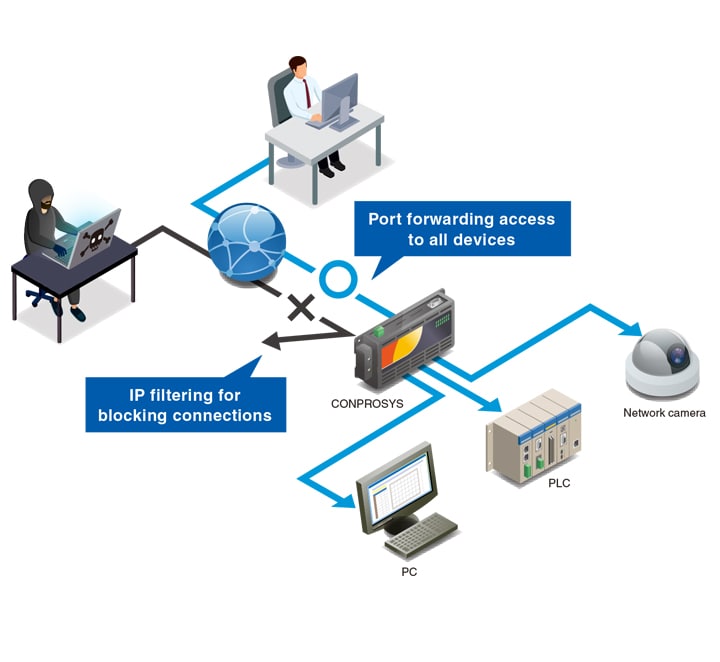

Simple Router Functions

CONPROSYS IoT gateways now include new router functions. The specific functions include basic functions such as DHCP server functionality, static routing, port forwarding, and IP filtering, and although they do not reach the level of functions used in dedicated operational devices, they are sufficient for use as an IoT gateway. Because these functions eliminate the need to prepare separate router devices, the equipment box is small and the device configuration is simple. The reduction in costs is the most welcome characteristic.

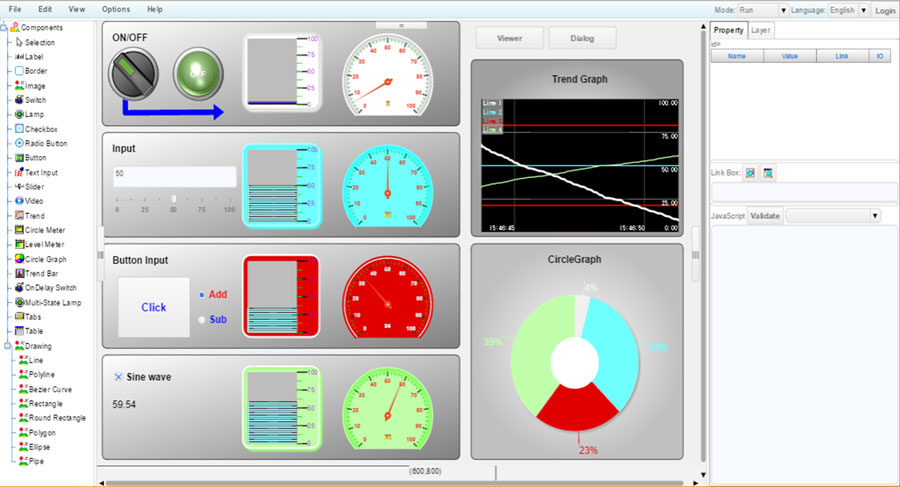

SCADA/BI Tools Unnecessary?! Standard-equipped with Web HMI Functions

Programmable displays are frequently used when visualizing data and performing command control for PLC and other controllers that are used in factory equipment and control equipment. This is because PLCs do not include screen display functions or functions for storing large volumes of data. It is reported that when viewing the display screen from a remote location or when the amount of information is large, it is necessary for the user to prepare a separate SCADA software or BI tool environment.

The CONPROSYS IoT gateway includes standardized and easy-to-use functions for visualization and functions required by the IoT system, allowing a corresponding reduction in costs.

An HMI screen can be easily created simply by accessing the CONPROSYS IoT gateway from a web browser, calling the HMI screen creation function, positioning the graphs, meters, sliders, buttons, and other display parts which were prepared in advance, and linking them to the data. One characteristic is that because the web browser serves as the viewer, there are no restrictions on screen size. With a programmable display, for reasons of the screen size, depending on the amount of information, it may be necessary to switch among multiple pages. However, with the CONPROSYS IoT gateway, it is possible to position and display a large number of display elements in a large screen space.

By placing the CONPROSYS IoT gateway inside a control panel that contains the PLC or other controller, it is possible to complete everything including the visualization functions with a single control panel.

Examples of screens created with CONPROSYS HMI

Examples of screens created with CONPROSYS HMI

Click Here for Details of CONPROSYS HMI Functions

Standard-equipped with Low-code Script Functions That Can Visually Configure the Rule Settings

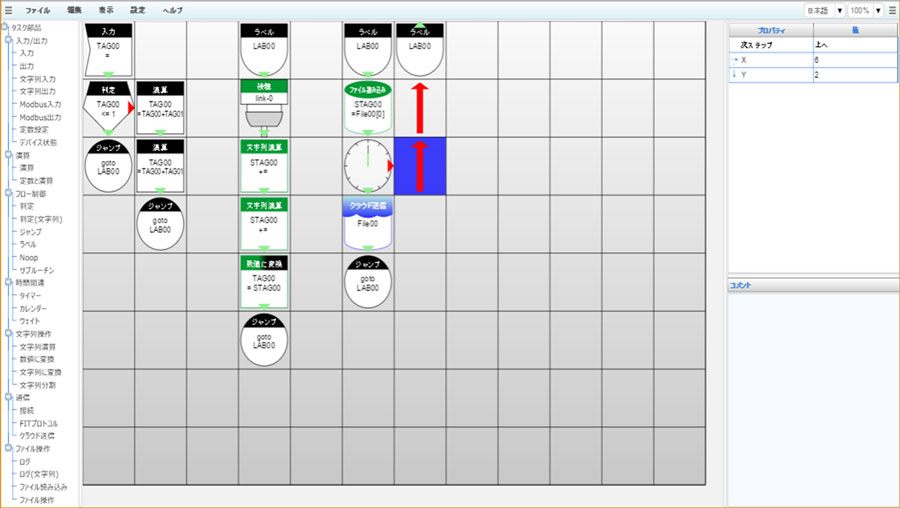

The CONPROSYS IoT gateway includes the CONPROSYS VTC (Visual Task Control) low-code script function that allows task settings to be configured visually in a manner similar to creating a flowchart.

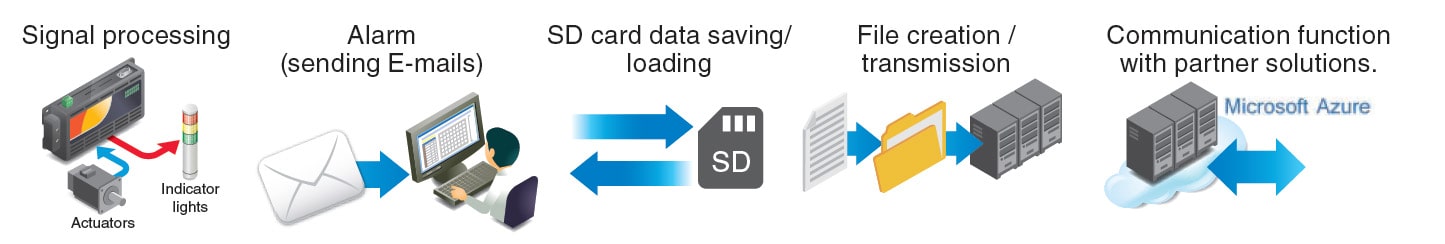

Task settings can be configured visually with a combination of 50 types of function icons such as input data calculation, data transmission, character string operations, conditional branch, and file operations. The function icons also include sending email, data save/read to/from an SD card, and data transmission to Microsoft Azure IoT Hub, and are sufficient for the required functions. With the ability to set 20 tasks and 10 subroutines, one feature is that even when edge processing on a considerable scale is required, it is possible to complete the necessary processing with just CONPROSYS IoT gateway on its own.

A large number of CONPROSYS VTC sample programs are available under “Script Sample Programs” on the Contec website (contec.com). They are organized into categories so they are easy to find, including Communication, Sensor Connection, Control, Monitoring, and Data Operation/Conversion.

Examples of function icons

Examples of function icons

Click Here for Details of CONPROSYS VTC Functions

Conclusions

The CONPROSYS IoT gateway is a convenient product that is packed with user needs, servicing as a device which adds remote monitoring and breakdown prediction IoT functions to existing equipment. It also provides functions for data collection/conversion in order to carry out DX of factory systems.

The applications of IoT systems are expanding in a wide range of industries including electricity, electrical equipment, logistics, materials chemistry, and food products, and the new functions introduced here allow them to be used in an even wider range of industries.

Contec will continue to take inspiration from user requests, and equip its products as standard with the functions required by the times. In doing so, we will provide simple, convenient, and easy-to-use IoT solutions for every era under the CONPROSYS brand.

Furthermore, as a comprehensive electronic device manufacturer specializing in industrial applications including computers, measurement control devices, wireless communication, and network devices, the company will aim to support customer innovation issues such as IoT, artificial intelligence (AI), DX, and green transformation (GX).

Related Contents

Back to Blog Top